-

Posts

295 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Downloads

Gallery

Posts posted by Thang Nguyen

-

-

Hi,

I was asked by my supervisor about LIMS compatibility of our software. I did some research including search on LAVA still cannot get much information about technical side of LIMS. somehow I only know that it uses the OPC protocol but beside that I don't have any more information. Could you please share with me some information about LIMS and how do we communicate with LIMS from LabVIEW side. I worked with OPC server before.

Thank you in advance.

-

@Neil: Yes, this is what I need. Thank you very much.

-

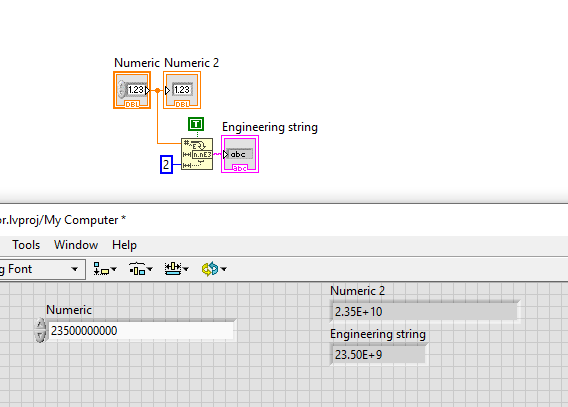

I want 1.2ex10 not 12.0ex9 as you can see in my example. I will check format into string.

-

I need to display the engineer string in a tree so I used number to engineer string.

The issue is it is very limited to format the engineer string with this function. Look at below example

I want only one digit number before the decimal point but I don't know how to set that. Please let me know how to do it.

Thank you in advance.

-

Thank you very much!

-

Hi all,

I would like to know if there is a way to access to the reference of the runtime shortcut menu of a control? I would like to enable/disable one of those menu item programmatically. I only know how to access the runtime menu of the VI.

Thanks in advance.

-

Thank you very much.

-

James,

Thanks for your response. I tried to modified one of your example to create two tables. One thing I noticed is BEGIN.vi returns error 5 when it waits for a while but there is no timeout input. Should I just clear the error and run the Execute SQL vi again?

-

Hi,

I would like to know if I can write stream data into two different tables with SQLite at the same time or not? Currently my system has one camera. I store the capture images and particle measurement in one table. I have just add one more camera to the system and would like to do the same thing and write to a second table in a parallel process. I wonder if this is possible or not.

I use SQLite library.

Thanks in advance.

-

Thank you very much!

-

There is nothing perfectly fit for everything. Pick the one closet to what you want and go with it instead just wondering about it. Use your brain to learn how to program LabVIEW first.

-

I am working on a project need to tracking objects in real time by vision. I need to populate the information on the host software. This is still in the process of developing so I want to have the time of the device populate on the screen of the host software like in MAX. Is there a function allow me to do that?

Thanks in advance.

-

Thanks Ensegre. It looks promising. I will check more detail.

-

Hi,

I wonder if we can create application with multiple sub windows like TestStand using LabVIEW? Currently, my application has multiple dynamic call VIs. I can arrange them by specify the location and the size. But I still prefer to have them stay inside something like subpanel but can change side as well as location.

Thank you in advance.

-

My company is growing so need to add one more position for LabVIEW developer.

Best to have experience working with complicated architecture

Need to help object oriented knowledge and experience.

Good to help experience with NI Vision, Motion, FPGA.

We can transfer H1B.

Please send email to thang.nguyen@lumacyte.com

This position if filled. Thank you.

-

If you are the one order the NI parts relating to motion you will receive the letter.

-

We are using NI Softmotion, cRIO and NI 9503 to control stepper motors now. But since NI will discontinue these products we need to look for replacement. I just want a controller which I need to send command to tell motor move for a certain distance with a pre-program acceleration, velocity profiles.

Thank you for answering my question.

-

Hi,

I am looking for an option to replacement of NI Softmotion + Stepper modules to control 3 axis stepper motors. If anyone has experiment with this please give me an advice.

Thanks in advance.

-

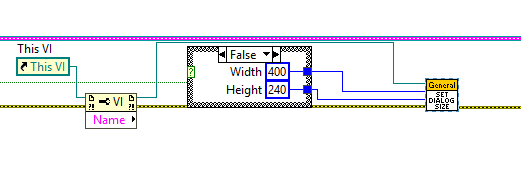

@ensegre: I am actually aware of the panel limit size. I did set the minimum size to the smallest value I can set to. But after setting it to 1x1, I don't get error anymore. I guess this fixed it.

Thank you very much.

-

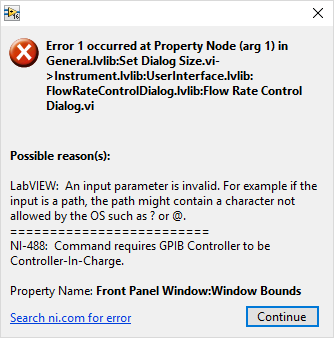

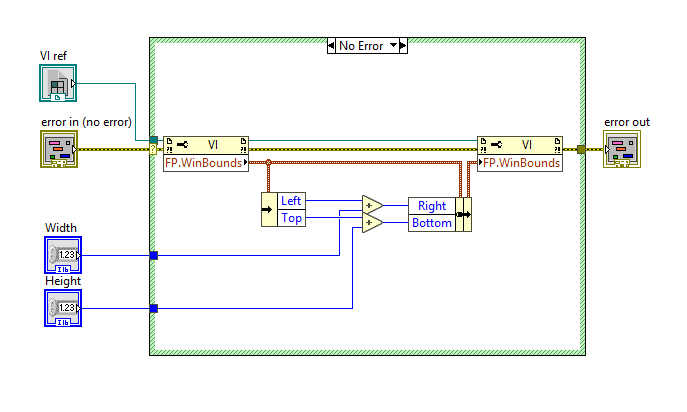

In my application, I try to change the size of the Front Panel of sub VI based on configuration. I am not sure why I got error below.

subVI Set Dialog Size's block diagram

When call this VI, I tried to passed in VI server reference or pass using VI property node reference. Both of methods return same error

Thank you in advance.

-

In attachment is my FPGA VI. I have 2 motors. With one motor, I have a single cycle time loop to generate a PWM and another single cycle time loop to analyze the encoder. I would like to ask, if I want to add PID in FPGA, should I create a third while loop to connect encoder value with PID and the PWM generator? This is the only way I think it can happens.

Regards,

-

Hi,

I am quite familiar with different design pattern on LabVIEW but I am a newbie on FPGA design. I start working on a project for my own hobby using myRIO to control motor speed with PWM and read back encoder. This is the first part of my project and I plan to expand more later. This project will help me to get use to FPGA too. I am trying to learn a good design pattern by follow the template project which is "LabVIEW FPGA control on Compact RIO". In this template project, feedback value and control signal are analog channels and they connect directly with PID module in FPGA in a normal while loop. The configuration are sent from host. In my prototype project, I already built FPGA module to drive PWM and read encoder using single-cycle time loop. I plan to use PID in real time code. If I want to follow the template design, I have to change the way I implement the code for FPGA and Real-Time. So right now, I am not sure what is a good design I should follow. If you have any advice, I will highly appreciate.

Thank you very much!

-

1

1

-

-

Thanks Chris and Yair. I decided to swap the Y to keep it simple

. At the beginning I miscalculated the offset for origin, but I have correct value now.

. At the beginning I miscalculated the offset for origin, but I have correct value now. -

Hi,

In current picture control, the origin start at top left corner and it's positive direction go down to the bottom. I would like to use picture control to draw map for my robot project, but I would like to display as a normal coordinator system which mean vertical positive direction is go up and origin start at bottom left corner. I am trying to shift the origin and swap all y value. I wonder if there is better way than this.

Regards,

Thang Nguyen

Ask about LIMS

in LabVIEW General

Posted

@JKSH: Sorry for late reply.

My software controls an instrument in the lab to run cell analyst. One experiment session is start with pressurize the cell through a channel and using machine vision to analyze image captured of the channel. The experiment data is captured in database include of hardware data like pressure, voltage.

In some lab they use LIMS to manage the workflow. I still not sure how should I integrate my test data into LIMS.

Thanks for your information.