alexb

-

Posts

8 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Gallery

Posts posted by alexb

-

-

When I run a general program , it contains lots of programs , subprograms and vi's.

If I wanna , for example , to send my program to a friend. How can I see a list of the subprograms and vi's that my main prog is using while it's working , so I could send him the whole package ?

thank you.

-

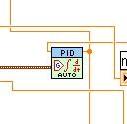

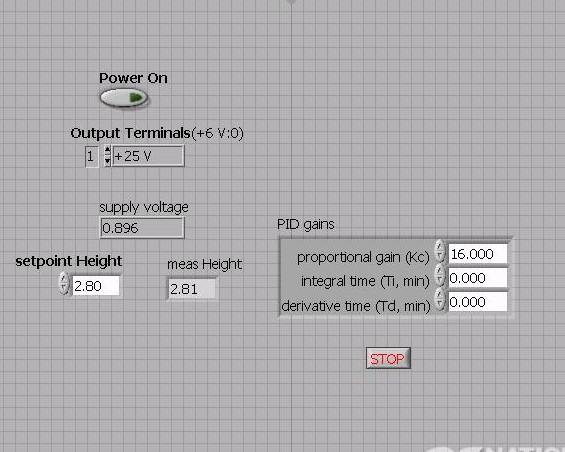

Try converting all inputs (level) and outputs pump speed to %, there are egu to % and % to egu vi's for this purpose.

also make sure you understand if you are forward or reverse acting. In other words, what is ther relationshiop between input and output. If it is reverse acting then make you PID k gain negative.

where can I download vi's such the one u've mentioned ?

-

You haven't understood how PID works at all. You MUST use the Process Variable input; in your case it's the measured height of liquid in the tank. The PID VI calculates the error internally by finding the difference between the Process Variable and the Setpoint.

I understand that , but when I use this input. The Pump stops working.

I shows that the pump works on -2 volts. Very weird.

Is there something that I'm missing ? maybe I suppose to inverse the input in the Pump when I work with the PID VI ?

-

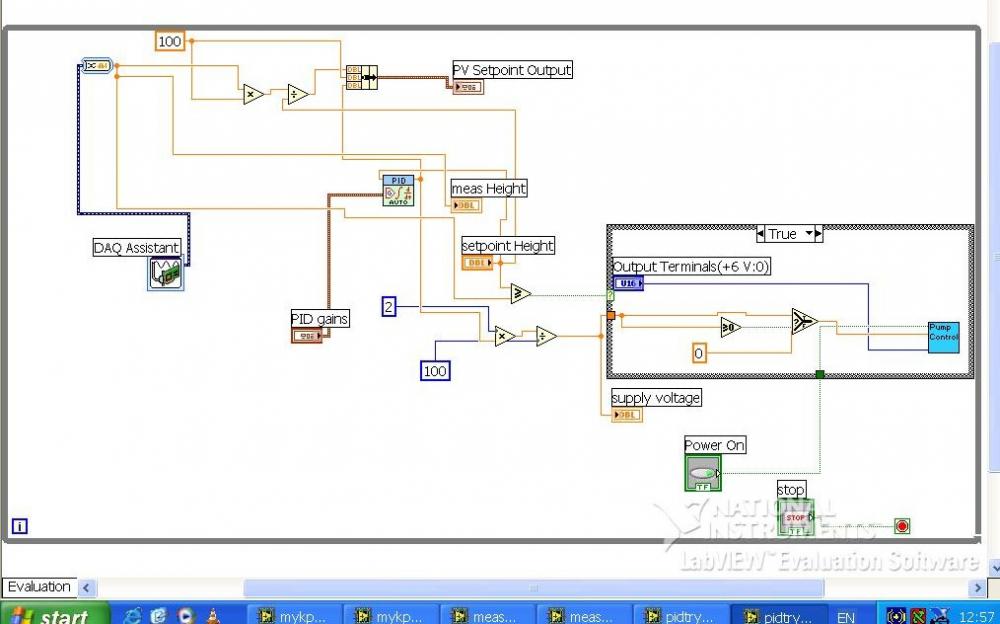

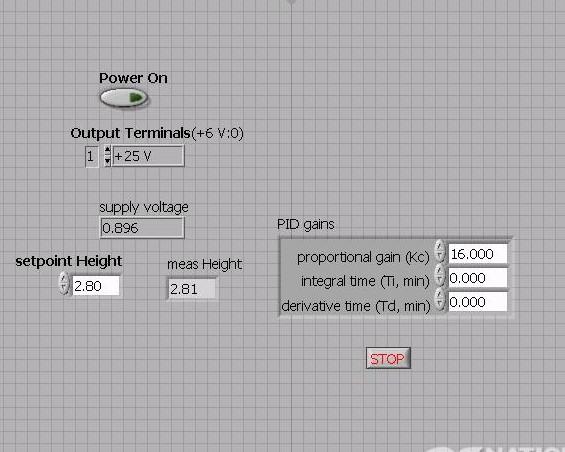

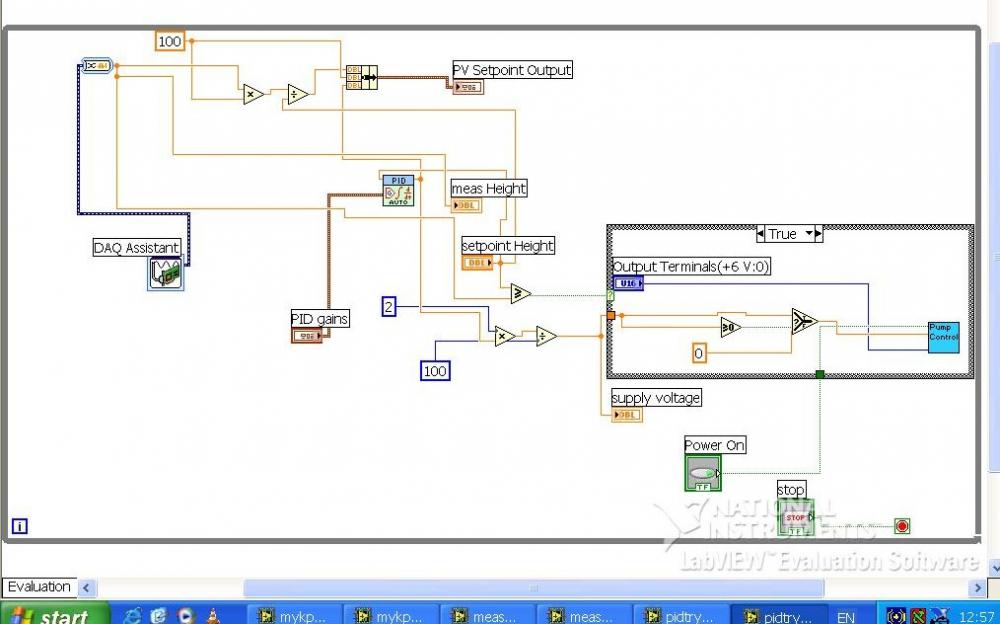

hey guys,

I need your help. I'm working on a project - level control in a tank with water.

I suppose to control the level of the water , for example - the user can choose the height he wants the water to fill the tank , and a pump starts to pour water into the tank.

I work with the PID VI. The user can choose how to control the water with the controllers - P , Pi , Pd or the combined PID.

For example , the P control works like the equation m=P*e

m - stands for the strengh of the water pumping

e - stands for the error - difference between the height I want , and the height found in the tank.

p - is a constant

As bigger the difference between the wanted height and the found height , as stronger the strengh of the pumping.

While the tank is being filled , the pumping suppose to get wicker until it stops.

This algorithm that I wrote shows :

The user chooses the set point - the height he wants.

The DAQ measures the height - (height * 100) / wanted height --> gives us the error.

But , while the tank is being filled , and the error is getting smaller , the pumping strengh stays the same.

P.S

I didn't use the entrance that called Process Variable in the PID VI. That's where I suppose to attach the "error". But when I do that the pump stops working.

Please help I don't know what to do... : (

It's my final project and I'm desperate.

-

hey guys,

I need your help. I'm working on a project - level control in a tank with water.

I suppose to control the level of the water , for example - the user can choose the height he wants the water to fill the tank , and a pump starts to pour water into the tank.

I work with the PID VI. The user can choose how to control the water with the controllers - P , Pi , Pd or the combined PID.

For example , the P control works like the equation m=P*e

m - stands for the strengh of the water pumping

e - stands for the error - difference between the height I want , and the height found in the tank.

p - is a constant

As bigger the difference between the wanted height and the found height , as stronger the strengh of the pumping.

While the tank is being filled , the pumping suppose to get wicker until it stops.

This algorithm that I wrote shows :

The user chooses the set point - the height he wants.

The DAQ measures the height - (height * 100) / wanted height --> gives us the error.

But , while the tank is being filled , and the error is getting smaller , the pumping strengh stays the same.

P.S

I didn't use the entrance that called Process Variable in the PID VI. That's where I suppose to attach the "error". But when I do that the pump stops working.

Please help I don't know what to do... : (

It's my final project and I'm desperate.

-

I'll try. thnx guys!

By the way I'm using it for my final project in the University.

-

Didn't know under what category it falls but here's the prob -- > I work with DAQ 6008 (for Measurements).

For instance , i wanna measure Voltage. But i can use only one channel in the DAQ. If I use another channel to Measure something else , It says that The DAQ is already in use.

How can I write a program that can run measurements simultaneously in 2 channels (or more) ?

How do I write this program? Am I suppose to Duplicate the DAQ VI or can I use only one VI with two exits (for the 2 channels) ?

Time Measurements

in User Interface

Posted

If I wanna for example measure Voltage during a period of time and connect it to XY graph the shows :

X - shows the elapsed time

Y - shows the voltage

How do I do that ?