-

Posts

26 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Gallery

Posts posted by gyc

-

-

Hello Benoit.

I get error 1507 when running the demo. What could be wrong with DLL's?(I am using the lvlib from a project)

-

On 16/01/2017 at 5:52 PM, ensegre said:

Not arguing, just learning (always learning).

Excellent implementation, btw!

-

On 12/01/2017 at 9:51 PM, Tim_S said:

Wat you are describing is the concept of an integral. Rather than sum up a large rectangle (which you don't have), you break up the object into little rectangles and sum those up.

Exactly, but I find it difficult to 'split' the figure into rectangles.

What I thought of is to split it into triangles, of which one vertex is the center of mass of the figure itself. (good old romans already did that!)

-

On 12/01/2017 at 7:34 PM, infinitenothing said:

How accurate do you have to be? Maybe implement your own flood fill? Otherwise, you have to define some sort of point to point interpolation which could be as simple as defining a polygon

Accurate: not a problem. It depends on how many (x,y) points i have, so I can control that beforehand.

Floodfill: I am not working with images/pixels. (x,y) are actual floating point values in a measurement space.

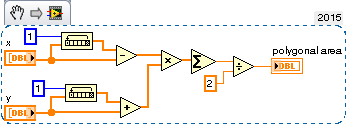

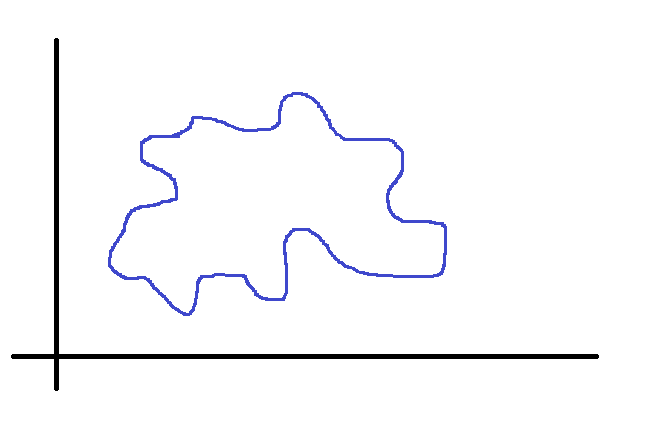

This is green theorem (which in turn is a particular case of Kelvin-Stokes) but I can't seem to find anything in LV help.

-

Hi there.

I need to compute the area within a closed shape (on XY plane) defined by an array of XY points (XY graph).

Can't find anything for labview related to this. (not using Vision, of course)

"splitting" the curve in two halves, integrating both along the diving (straight ) line and subtracting the resulting areas does not always yield a correct result because the shape may not always perfectly regular (check picture).

Any suggestions?

-

-

Thanks, I had seen that too.

Not that it is technically difficult, it's just quite long...

-

As many may know, Q-DAS has established a de-facto standard for statistical quality control data exchange (files .dfq, .dfx., .dfd)

Is there, somewhere, a vi to write data to file in this fomat?

Cheers

-

Hello all.

I need to deploy an application that uses an USB DAQ device.

The customers are not NI/LabView savvy, so NIDAQmx installation must be pre-defined and "silent", i.e., requiring no user interaction at all (I have already created a specfile for that).

Now the questions:

1)when creating the application installer in the project, how do I specify to install NIDAQmx with a specfile and other options?

2)can NIDAQmx be installed by a computer user without admin previleges(I am deploying version 8.9.5) ?

Thanks.

G.

-

As ShaunR pointed out, 20000 points are too much to display - simply there are no monitors with that many pixels.

Furthermore, the human eye will see as continuous anything refreshed faster than 16 Hz, so it's pointless to update the display at any faster rate than that - it's simply a waste of time and valuable computer resources.

Except for very display sensitive applications (multi-media, simulation and very few others) simply just use the most practical method to display for your case (refs, sub-panels, queues, globals, functional globals, etc., it depends on what you're doing and how), decimate data AND updated displays only every 60 msec - 50 if you really cannot settle for less - but even 100 msec should be enough.

-

Naw! They don't seem to read the internal HW serial number of the drive. What they seem to do is preparing some 2MB of data space on the flash Drive with some specific data that is read back by a specially prepared DLL that will return this data after some encryption/decryption. Supposedly they do something to prevent the simple cloning of the flash drive by ghost or similar software. How they do that is not clear and

How else can a chunk of data be "tied" to a piece of hardware?

In that data there must be "something" specific of that hardware, that does not change with platform, with OS and cannot be easily tweaked by a smart user...

I doubt they will tell you.

However it does not seem to read any serial number of the flash drive itself.

However it does not seem to read any serial number of the flash drive itself.Of course they will not tell!...

although secrecy is the worst method for security. Sooner or later (usually sooner) that information leaks out

and for all those relying on it it's "duck open season".

and for all those relying on it it's "duck open season".

-

Not quite what I'm looking for.

The idea is to turn common USB flash drives into security dongles.

In general, it's hopeless unless you have a specific USB drive for which you know a proprietary access method to retrieve its chip serial number.

I've seen some discussions and some code samples around.

I just haven't yet had the time to look into it.

And someone else is already doing it: http://www.alkonost.com/antiduplicate/

G.

-

Wow. For once LabVIEW didn't crash when saving to a previous version.

Super!!! Thanks.

I flirted with it a while back (its on here somewhere). The issue is Admin rights. I never got around to revisiting it.

If you happen to dig it up again, pls drop a line!

Thanks again.

G.

-

A simple (not fool-proof) way is just to read the volume serial number of the USB stick. There's the "Windows API" in the CR tat will allow you to do that.

Not fool-proof is exactly the problem.

However the API is quite interesting. Any chance you have a pre-2009 version lying around? (8.x would be nice!0

Alternatively, you could read the device ID out of the windows registry.

Tha is also prone to change.

I need to get the HW serial number from the chip. I have seen posts about it and some talk about example code, that's why I thought someone in the LV sphere could have already done it.

G.

-

This is also part of the online manual that gets installed with your LabVIEW software. Read the last paragraph to find some samples that are also installed with your LabVIEW installation!

It took about 10 seconds to go to www.ni.com and type in "LabVIEW ActiveX Server" in the search box and it was one of the first links on the list.

Thanks Rolf.

It's not that I did not search for the info. I did and I had come across that page, but after reading 3/4 of it it seemed that it was all about creating a server and had no info on how to call it from another language - which is absolutely congruent with its title.

So I just quit reading and - obviously - missed the last paragraph.

The information is mixed and lies in a single 2 line paragraph at the very end of the page. I would think that maybe that is not the best way to present and - mainly - find it.

Probably, it would be useful to have one page dedicated to calling an LV built ActiveX server from other languages (VB, C++, Delphi, etc) with the 'right' title.

G.

-

Hi.

I have an application built in LabView that a customer asked to "control" via ActiveX.

I built it with "AcitveX tick" enabled and tested it with an LV client and it works like a charm!

As it turns out, although the customer develops his own sw in Visual Basic, they don't know how to "connect" to my ActiveX server. (apparently, they only know how to use ActiveX controls)

Since my knowledge of VB is also very limited, is there anyone that can send me a skeleton example of how to connect to an ActiveX server (developed in LV, although I'd think that's not important), write to a control and read from an indicator?

Do they have to "do something" in their VB development environment so that they "see" my server?

Maybe some of you would direct me to a VB forum, but since I lack VB expertise to know how much this could be LV specific, I preferred to start here.

Thanks.

G.

-

Hi.

I've seen someone using normal USB pen drives as security dongles for sw licensing.

They actually sell a sw package that will turn any usb pen into a security dongle.

As it seems, it is based on the usb pen hw serial number.

Does anyone know how to retrieve this serial number?

Usual API calls wil not work on usb pens mounted disks, so there must be something more to it; I couldn't find information on the internet.

Cheers.

-

Hi there.

I'm sure many of you are 'acquainted' with the "generateComputerID.exe" little prog used by the license manager to generate a 16-digit code unique to the computer (based on hw - mac address and processor serial no. - anyone correct me if I got it wrong).

Does anyone know how to do the same programmatically in LabView?

I know the little prog can be called with a system exec, but I think this is not very elegant - and I am forced to deploy the prog with my application.

G.

-

Hi there.

Has anyone tried LV on the Ledato platform?

Ledato runs a Debian distribution, which should be ok...

Anyone?

-

So all we're talking about here is having the hooks added and possibly Darren's code or ours should we choose, right?

If you code monkeys force me to 4224 instead of 5335 and tag .ctl or .lvclass on the end of all of my controls more than you already do, I'm going to take my pikachu down to the 3rd floor and demonstrate some hand to hand knife fighting moves on him.

Nice pics you got there!

What's about the "popcorn tweets"??? Sounds like a great fun...

Where can I see (a video of) this demo???

-

Hi all.

Does anyone know if the digital lines of PXI-7813R have a pull-down or pull-up resistor in their internal cicuitry?

From the manual, I would conclude that there is no pull-up, since one needs to add it when DIO lines are programmed for output AND are driving 5V logic, but nothing is explicitely stated about pull-downs.

Thanks in advance to all that may help.

-

the string input is the problem.

the help you need can be found here:

http://zone.ni.com/devzone/conceptd.nsf/we...6256869005ff2ed

good look

CB

I tried to pass the string as "handle" and as "handle pointer" but it doesn't work: LV is just kicked out with absolutely no messages.

Thanks anyway!

Gyc

-

Here's the prototype:

int ADAMTCP_Connect(char szIP[],

unsigned short port,

int iConnectionTimeout,

int iSendTimeout,

int iReceiveTimeout);

-

I am trying to use an external DLL with LV.

This DLL is known to work with VB and C++; however, when I call it LV traps a low level memory corruption error and stops the VI.

What might be the problem - or what am I doing wrong?

Gyc

[CR] 1-Wire.zip

in Code Repository (Certified)

Posted · Edited by gyc

Hi.

I have 1 temperature sensor (DS18B20) connected to USB - serial COM5. DS9097E is correctly detected by Maxim's software.

I modified the config file as follows:

[1-Wire]

PortType=DS9097E

PortType possible values=DS9097E, DS1410E, DS9097U or DS9480, DS9490R or DS9490B

PortNumber=5

EnhancedOptions=Not use

EnhancedOptions possible values=Not use, SESSION_INFINITE, SESSION_RSRC_RELEASE, SESSION_NO_FORCE_REG_SPD

I changed the all the nodes to winapi call mode and the error was gone.

Now I have another problem: the "find devices" does not find anything and I have this strange error:

Where can I look and what should I look for?

Also, I can't seem to find a VI for temperature reading. Is it because there none or because I didn't look carefully enough?

PS -

Another detail:

With program "digitemp.exe" (can find it in https://usbtemp.com/) everything works correctly, so I am sure there is no problem with hardware.