Ashish Uttarwar

-

Posts

36 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Gallery

Posts posted by Ashish Uttarwar

-

-

Hi~

in LAVA Lounge

-

QUOTE(ASTDan @ Jan 22 2008, 01:48 PM)

.... the .iak file of interest loaded into MAX on my target machine, and I call the fieldpoint i/o with respect to the project.....Also, through MAX, you need to synchronize the software/drivers between PC and cFP controller.

Also, create a "startup" executable to make sure it runs on power up!

-- Ashish

-

QUOTE(dsch @ Jan 20 2008, 10:25 PM)

I have found some PCI DAQ cards........supply the power (12VDC) or do I have to supply that separately?If the project is just for fun and experimentation purposes, the simplest hardware solution I can think of is

- separate 12 V power supply

- NI USB DAQ device

If it is a part of bigger system under development,

- NI PCI DAQ device will be a better option

I hope this helps.

ALL THE BEST!

- Ashish

-

QUOTE(bono02 @ Jan 16 2008, 12:36 AM)

.....LabView is more close to real application (GUI) and hardware interface.bono02,

I think jbelim did a right choice by choosing LabVIEW for this project. LabVIEW is more than just GUI and hardware interface. The NI Vision is full fledge vision analysis toolkit and easy to implement.

I hope it makes sense and jbelim feels motivated :thumbup:

-- Ashish

-

QUOTE(venkatesh @ Dec 6 2007, 06:28 AM)

... computer which is in remote ....If you are talking about "Remote PC Access", I prefer Real VNC software (you need it installed on both PC, Remote and Local).

If you are talking about access of a Remote PC from LabVIEW on local PC, that is a different story.

What do you want?

--- Ashish

-

QUOTE(John Dierks @ Nov 27 2007, 07:44 PM)

....I can get some real world experience and start sending out some resumes!....Welcome to the LabVIEW world!

I will suggest to look for right people to work with instead of "Job Openings". It sounds more philosophical but it will help in long run!

There are good resources of "NI Alliance Members" available on NI website (I do not have the link). That is good place to start.

ALL THE BEST! :thumbup:

Regards,

Ashish

-

QUOTE(CraigGraham @ Nov 26 2007, 05:58 AM)

......"Exit without closing RT Engine VIs".I am using LabVIEW 8.2.1 for programming cFP and the only way to upgrade the VI on cFP is by building EXE and setting the EXE as "startup" before deploying. I am pretty sure that it should be possible on LV 7.1 too. Setting as "startup" and deploying will configure the cFP to run the EXE on power up. This way, you do not have to "Exit without closing RT Engine VIs". Also, cFP power reset will not matter.

I am also looking around for programatically upgrading software of cFP, so that multiple cFPs can be upgraded from a PC on same network.

--- Ashish

-

QUOTE(CraigGraham @ Nov 26 2007, 05:58 AM)

......"Exit without closing RT Engine VIs".I am using LabVIEW 8.2.1 for programming cFP and the only way to upgrade the VI on cFP is by building EXE and setting the EXE as "startup" before deploying. I am pretty sure that it should be possible on LV 7.1 too. Setting as "startup" and deploying will configure the cFP to run the EXE on power up. This way, you do not have to "Exit without closing RT Engine VIs". Also, cFP power reset will not matter.

I am also looking around for programatically upgrading software of cFP, so that multiple cFPs can be upgraded from a PC on same network.

--- Ashish

-

QUOTE(akala @ Nov 17 2007, 04:06 PM)

.....NI Device Drivers ..... compatible with LabVIEW v.7.1 , 8.0 and 8.2 (not 8.2.1)??The latest Device Drivers should be compatible with all the LabVIEW versions, unless specified in ReadMe file.

I found that the driver installation allows you to install the drivers for more than one LabVIEW versions!

Try running the Device Driver installation and you will know what I mean.

--- Ashish

-

QUOTE(sachsm @ Nov 5 2007, 12:57 PM)

.....subsequent updates, even if forced via property value nodes or local variables does not visually update on the remote panel...I experienced problem with Property Node on RT system. But, Local Variables worked for me!

I wonder if you are running any kind of "Timed" loop. Did you try running the loop slower (~500 milli sec) interval?

--- Ashish

-

QUOTE(akjohn @ Nov 2 2007, 10:13 PM)

..... read the assigned name of these for display on the host control machine......I am using Compact Field Point cFP-2120 controller.

I found that there is a file "ni-rt.txt" on the controller which contains the accurate name of the controller. So, I created a VI to parse this file and get the name.

Since, you are also working on RT system, I believe the above mentioned trick will work for you too.

I hope this helps.

--- Ashish

-

QUOTE(José Sousa @ Oct 30 2007, 08:00 AM)

I am not sure but I will suggest to start your driver search from NI Drivers and Updates (http://joule.ni.com/nidu/cds/fn/p/lang/en).

I hope that helps.

Ashish

-

QUOTE(MikaelH @ Oct 18 2007, 03:05 PM)

.....application always takes advantage of the number of core the CPU(s) has.I am pretty sure that you are aware of this. But still....

Regarding core assignment in LabVIEW, I know that in LabVIEW 8.5, the Timed Loop structures can be assigned to specific cores on the processors.

--- Ashish

-

-

QUOTE(Popatlal @ Oct 4 2007, 08:19 AM)

You can buy the book from http://www.amazon.com/LabVIEW-Everyone-Programming-Instruments-Instrumentation/dp/0131856723/ref=pd_bbs_sr_1/102-6147684-7978502?ie=UTF8&s=books&qid=1191512645&sr=8-1' target="_blank">amazon.

Best wishes

- Ashish

-

QUOTE(pallen @ Oct 3 2007, 06:51 AM)

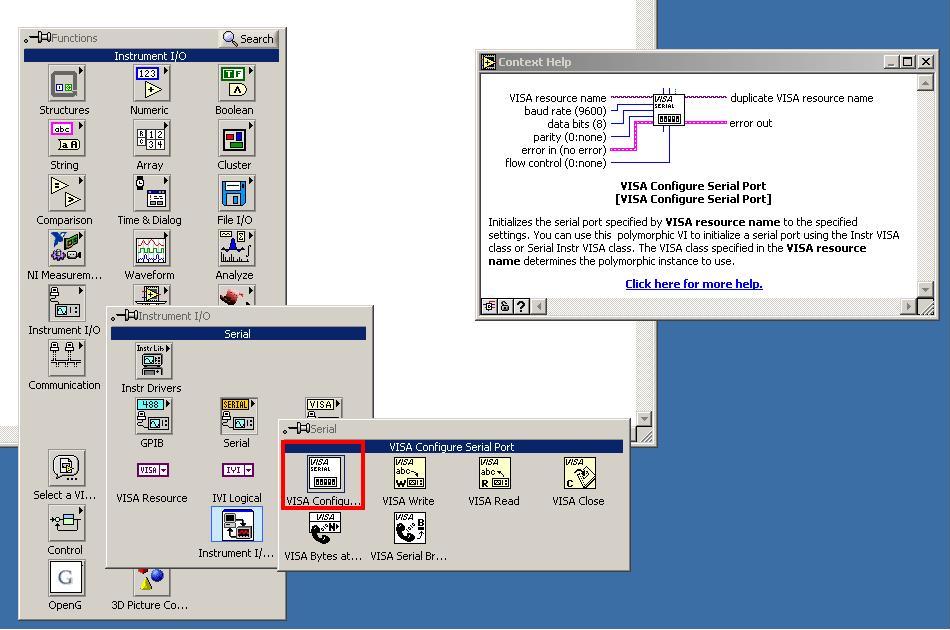

Did you try to configure the COM port using a VI?

Look at the following picture for location this on the pallette.

http://lavag.org/old_files/monthly_10_2007/post-2466-1191442108.jpg' target="_blank">

I hope this helps.

Regards,

Ashish

-

QUOTE(Popatlal @ Oct 2 2007, 08:52 AM)

is there any material or practical guide is available for begineer of labview...I much appriciate if any body helpful to me to geting the material

Welcome Mr. Popatlal!

I think the LabVIEW Example Finder will be a good place to start.

The book "LabVIEW for Everyone" comes with lots of nice and self explanatory examples too.

Also, keep up with LAVA for any specific help.

ALL THE BEST.

-

Thang,

You need to add a Fieldpoint target inthe project. This will allow you to add cFP channels.

There is a knowledgebase on NI discussing this. You can find it here (http://digital.ni.com/public.nsf/allkb/B2C...6257241006D7C77).

After you add the cFP in the project, MOVE the "Test.vi" under the cFP and open it. This will allow you to browse to the channels of the cFP.

I hope this helps.

Regards,

Ashish

-

I don't see a reason to have a "while" loop.

Attached VI is without while loop and it works too!

Regards,

Ashish

-

-

Hi 'fuzzycontrolfreak',

Welcome to the forum.

Similar to you, I started using LabVIEW for my graduation project too! It has a learning curve initially but I was totally impressed and made a career out of it.

ALL THE BEST TO YOU! :thumbup:

Regards,

Ashish

-

what kind of "interface hardware" are you provided with?

-

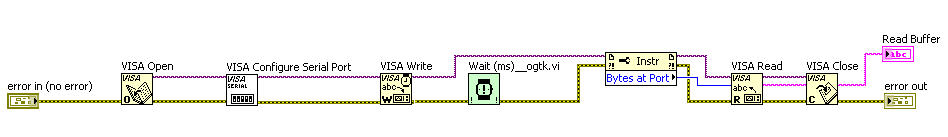

Thang,

I am assuming that you are communicating to the power meter via serial port.

This is what I usually do to write/read serial port.

You will have to provide the necessary information in each of the functions based on your device communication parameters.

There might be a better way to do it. Anyone...?

Hope this helps.

Regards,

Ashish

-

To rotate a dial you need to place the cursor over the end of the scale and you should get a rotate icon. Clicking and dragging at this point will control this.

You should note that doing this at the low end of the scale will cause the scale to be rotated as-is and doing this at the top end of the scale will allow you to control the size of the gap between the end and beginning of the scale.

WOW!!! :worship: That is perfect. Thanks a bunch Yen.

Also, thanks to njkirchner.

Regards,

Ashish

DataSocket Write Error 1179 while writing to a HTTP URL

in Remote Control, Monitoring and the Internet

Posted

Hi,

I am trying to establish a HTTP connection to a URL (eg: http://abcd:1010/my-web/clientConnection) in order to "write" an XML string and get a response back.

I was able to perform "read" operation on the URL using "Datasocket Read" function.

Now, I am struggling with "Datasocket Write" to send the XML String to the URL. I am getting Error 1179 after "DataSocket Write" function.

Attached is the Error message and the block diagram screenshot that is causing error. I tried various "modes" available in "DataSocket Open" function.

Am I missing something in terms of establishing connection to the URL? Should I use any other function (TCP/IP) instead?

Any other suggestions are also welcome.

Thank you.

- Ashish