Rexxar

-

Posts

4 -

Joined

-

Last visited

Never

Content Type

Profiles

Forums

Downloads

Gallery

Posts posted by Rexxar

-

-

Stan,

I hope you understand that the only reason I was playing around with the template is because I really admired the way that LabHSM worked. When you posted a simplified version that was different from a simplified version I had created, I wanted to see where the differences were and what could be improved on. I learned a lot about why you made the template the way you did.

I don't want you to think I was offering mine as a 'superior' solution. I was only looking for an alternative solution that made more sense to me. This was for my own personal use and not as a way to see if more people preferred my version. (From the dearth of outside conversation while we conversed I gathered that no one was interested very much.)

David

The message queue is meant for other VIs running in parallel that want to communicate with each other. If you do not need this then you can safely delete the code dealing with the message queue.

I was not documenting the template very much because Stan understood where I was going. I knew I would be changing things so I didn't document it each time. I added some more documentation to the Process Event VI with the example I am uploading here.

The following example should illustrate this a bit more.

Download File:post-1519-1169509991.zip

David

Hi dsaunders

Thanks very much for your fast reply.I need to pay more time to understand queue, previous I have had few knowledge and experience in queue.

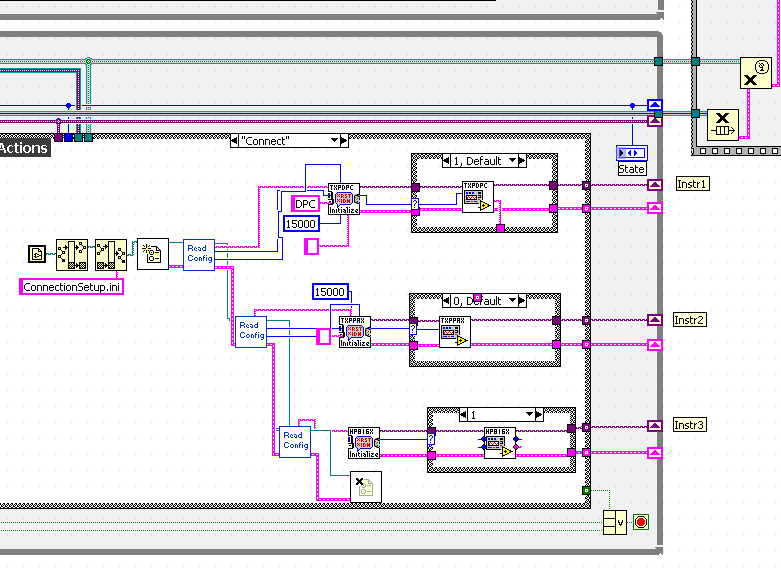

In this application I need to control 3 instruments, please have a look for attachment of my diagram, I do not know whether it is right way to control instruments and keep their instrument handles during the whole program. could you give some suggestion on how to control instrument and make read,save and analyse in your "pretty EDAM pattern".

Rexxar

-

Hi all

I have tried to use this beautiful

pattern but without understand entirely.

pattern but without understand entirely.I was confused by so much queues, how dose message queue works and what is his duty? The queue manipulate vis is not so clear without comment or description though we can open and read its diagram.

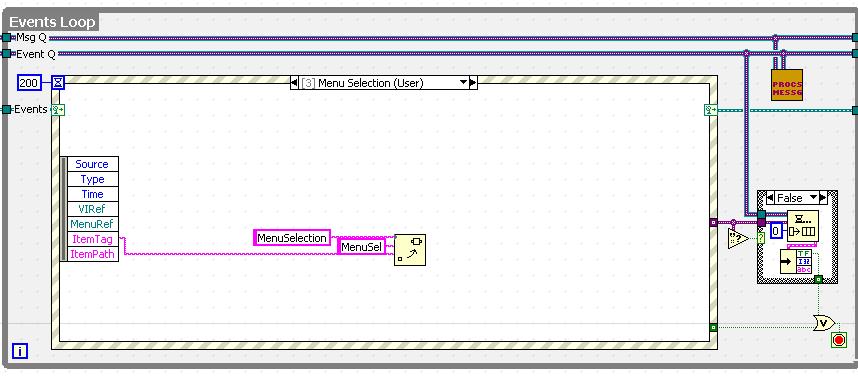

If I want to add my menu selection function to the pattern, to response all the customize menu item, how can I modify the pattern.

Please have look at attachment illustrating what I want to do.

-

Hi

I am designing a optical multi board control system which includes a Laser source, a Polorization Control module and a Polorimeter, the 3 modules are dependent with each other.

I need to open modules, active Laser source, use Polarization Control to change light parameter and use Polorimeter to measure the result.

Every module should be configed, measure prosess must contains control, acquire, save data, and so on, the software can analyze data without instument connection.

Always I like to use PC event pattern to construct my event driven system to make it looks like a classic windows software, day after day I find that event driven is not suitable everywhere and LabVIEW is not a traditional language with his own characteristic, more project I have finished, more puzzles for my architecture design, I browses NI forum everyday for good thead about architecture, but I am still a pupil in LabVIEW area.

Another thing is an instument keep alive information need to be sent with fixed interval, if I understood"keep alive correctly".

Thank you very much for your sinerely advice.

Return boolean from c++ dll to call library function node

in Calling External Code

Posted

QUOTE(rolfk @ Jun 12 2006, 09:30 PM)

In fact in C++ we have two types bool, the first is BOOL which is a macro in windows.h and has a 32bit ability, another is bool which is a regular type in C++,it's a U8 type. I have tried for several times for these two types in CLF, none is successful, I tried to pass bool using Adapt to Type, it seems to be successfun for only one time.