Search the Community

Showing results for tags 'labview scada hmi other software'.

-

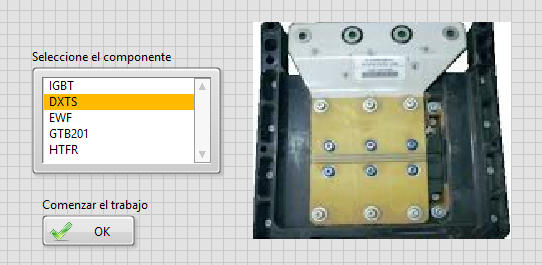

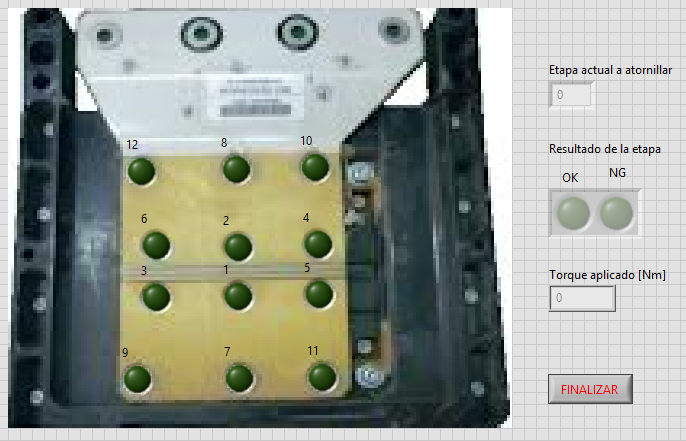

Hi, I'm involved in a project that consists on making an interface to supervise a job on real time and acquiring data from a controller to save it on a database. I'm going to use Labview because the enterprise uses it for some applications on testbenches so they already have the licence. But I need to make a report about what the other solutions are, with their advantages and disadvantages comparing to Labview for this specific application. I read some topics and I understand that in general Labview's strenght is acquiring and processing signals, but for simple SCADA it's better to use software like InTouch, iFIX or Citect. So I would appreciate if anyone can give me information about if those softwares could be used for my application and what are the advantages and disadvantages. I'll explain in detail my application: There's an electric torque screwdriver and it has its own controller. On the controller you can set up all the torque curves to be used in different components, saving them in up to 99 different channels. The enterprise I'm working in bought a couple of these to use them in some electronic components that require precision on the fastening of the screws. A big detail is that it's important to make the fastenings in a sequence. So what I need to do is an interface where the operator chooses from a list the component that he's going to make the work (when he clicks on the name in the listbox, it should appear a photo of the component so he's sure that that´s the one). Then he chooses to start the job. The front panel changes to show the component with LEDs instead of the screws, to show the sequence of the fastening (the LED1 starts turned on, then after the operator makes the fastening it turns off and the LED2 turns on, and so on until he finishes all the sequence). It also has an indicator to show the torque being applied, and two LEDs to show if the fastening was OK or No-Good. After the operator finishes the last fastening, he finishes the job and all the information is saved in a database (the serial number, total time, torque curves, results, etc) By the way, the communication with the controller is made with Modbus over TCP/IP. The provider gave a manual with all the addresses of the signals for the modbus protocol to make an interface on a panel pc. So, can all the other SCADA softwares do exactly that? Would it be easier? I have only worked with Labview so I don't know about the other stuff, a comparison with one or two should be enough. Thanks in advance, every information is useful.