-

Posts

0 -

Joined

-

Last visited

Actechnol's Achievements

Newbie (1/14)

0

Reputation

About Me

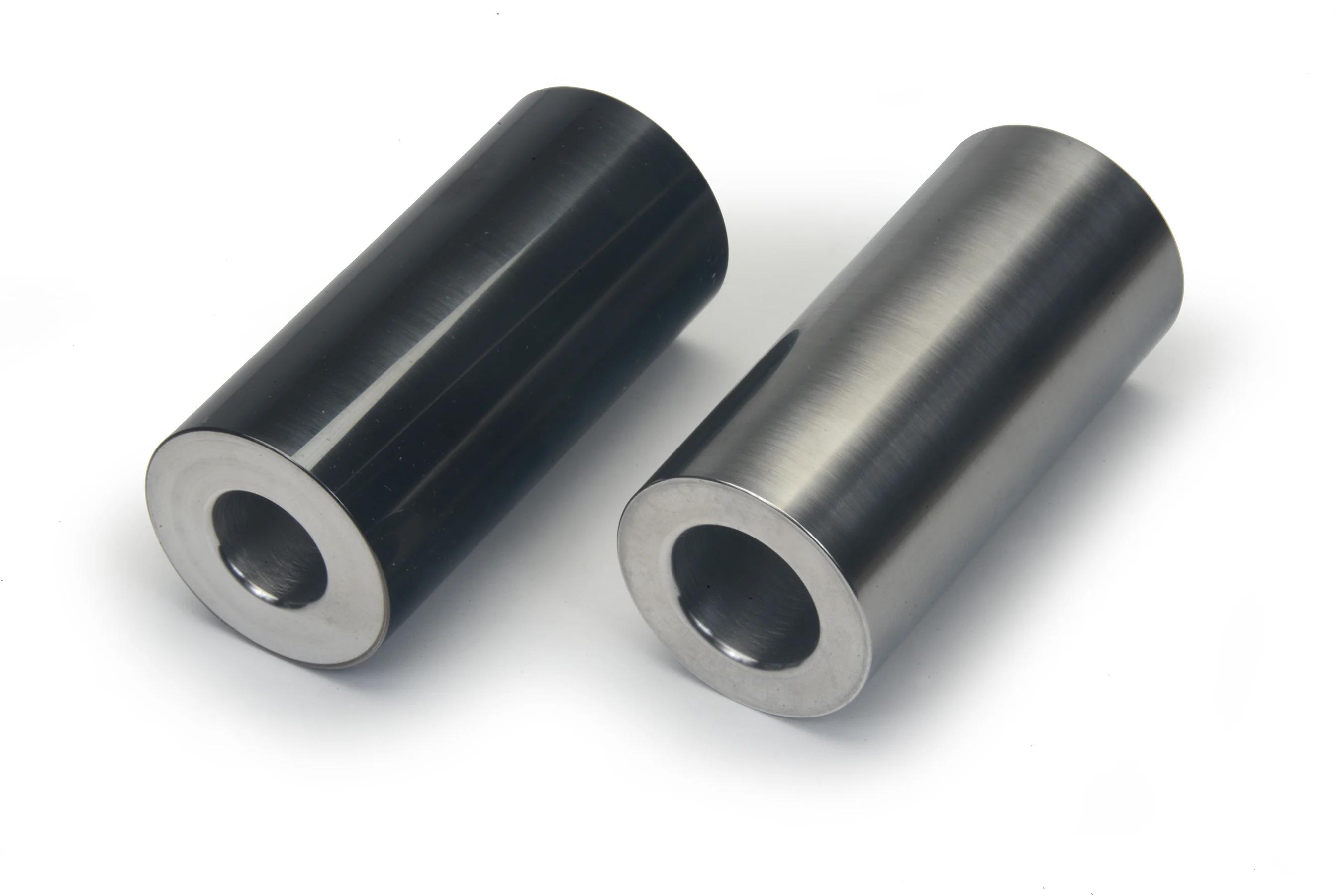

How PVD Coatings Reduce Friction in Moving Parts

Friction creates heat, and heat causes wear. A PVD coating service applies thin films that reduce surface friction, helping parts move smoothly under load.

A low friction coating changes how surfaces interact. Instead of grinding, parts slide more easily. This lowers operating temperatures and reduces energy loss. These coatings are common on cutting tools, bearings, and precision assemblies.

A controlled PVD coating service helps to ensure uniform thickness and strong adhesion. Because the coating is applied in a vacuum, it bonds tightly without altering the part’s shape.

Low-friction surfaces matter most where lubrication is limited or inconsistent. In dry machining or sealed assemblies, a low-friction coating provides protection when oil or grease can’t.

When friction drops, tool life increases, and maintenance intervals stretch. Over time, the benefits add up to lower costs and more predictable performance.