-

Posts

26 -

Joined

-

Last visited

-

Days Won

4

Content Type

Profiles

Forums

Downloads

Gallery

Everything posted by Łukasz

-

Pass complex data structure to C function

Łukasz replied to Łukasz's topic in LabVIEW Community Edition

Thank you @Rolf Kalbermatter. Your suggestion works as expected, and the code is much simpler than in the previous version. As I understand it, performing the opposite operation would not be easy since we can't resize the array. I wonder if there is any other function to allocate memory on the C side using LabVIEW, or if `NumericArrayResize` from extcode.h is the only option? -

Pass complex data structure to C function

Łukasz replied to Łukasz's topic in LabVIEW Community Edition

Thank you for your reply, passing a struct seemed very intuitive, and I considered a similar approach. However, I couldn't find any examples of how to pass an array of structs, which is the main blocker for this idea. Have you seen this approach used anywhere? -

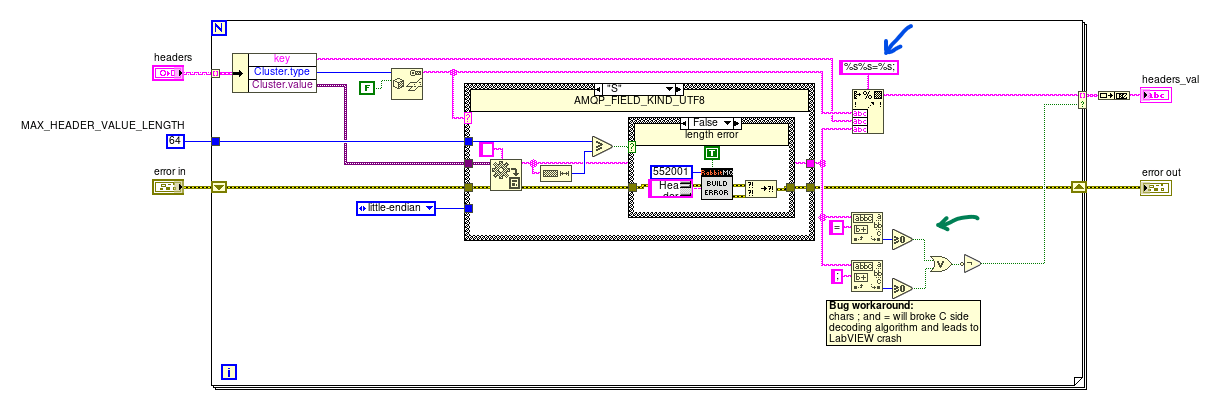

I need help passing a complex data structure — a map of clusters containing an enum type and a string value — to a C function. My initial solution was to convert this structure to a string and then to byte buffer, pass the buffer and its lenght, and then decode it on the C side. However, this approach has issues when the key or value contains characters that I used as separators. While I could improve my encoding method, I'm looking for alternative solutions to achieve my goal. Function prototype: int32_t lv_amqp_basic_publish(int64_t *conn_int, uint16_t channel, CStr exchange, CStr routingkey, uint8_t *headersBuffer, int32_t headersBufferLen, LStrHandle messagebody, LStrHandle error_description); headersBuffer is used to populate headers table (array of amqp_table_entry_t_): typedef struct amqp_table_entry_t_ { amqp_bytes_t key; /**< the table entry key. Its a null-terminated UTF-8 * string, with a maximum size of 128 bytes */ amqp_field_value_t value; /**< the table entry values */ } amqp_table_entry_t; LabVIEW code to encode headers map to string: The blue arrow represents the encoding signature for each element The green arrow indicates an issues with this method and ugly workaround I can modify both the LabVIEW and C code. Any suggestions would be greatly appreciated.

-

I tried all the solutions using LabVIEW 64-bit on Ubuntu. I fixed case 2, and cases 5 and 6 produced very similar results. I'm a bit worried about using BLAS VIs because they might cause problems during the building process. @cordm and @LogMAN I truly want to express my gratitude for your help.

-

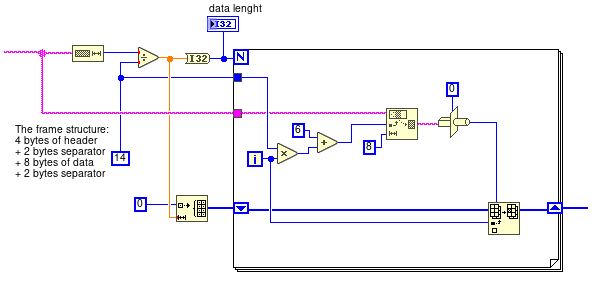

oh true, the frame is 16 bytes long. So your solution is the fastest now.

-

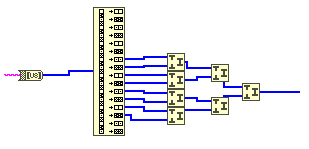

Your task is whipping up a piece of code that can unravel a string stuffed with uint64 data, all dressed up in that fancy communication protocol jacket. But hold your horses, partner! The catch is to make it faster than my own fancy footwork. Giddy up and get coding! Example of slow solution: Much faster solution: Y'all can lay your eyes on the testin' stuff right down yonder in that there attachment. And guess what? There's a little description of that frame thingamajig to tickle your fancy. So put on your explorin' hat and give it a gander! decode-frame.vi

-

I investigate that topic two years ago, and there was no easy CANopen solution for LabVIEW. Low cost solution can include kvaser hardware, but you will need to implement CANopen layer by yourself. Very high cost, but realy good and flexible is solution which includes vector hardware + vector Canoe envirement that easly share variables with LabVIEW. However I think this solution is for long term project and CANoe enginner will be required to set up the envirement. I will also check the oportunity to use python library for example: https://canopen.readthedocs.io/en/latest/ so you will trigger python script from LabVIEW.

-

Regarding which port was used it should be possible to get that information from winsock library on Windows. I think the answer can be found here: https://forums.ni.com/t5/LabVIEW/Is-it-possible-to-extract-the-local-port-associated-with-a-TCP/td-p/459672

-

So I removed the defualt version of libzmq3-dev package from Ubuntu and installed manualy the version with draft api enabled (for Ubuntu 20.4) echo 'deb http://download.opensuse.org/repositories/network:/messaging:/zeromq:/release-draft/xUbuntu_20.04/ /' | sudo tee /etc/apt/sources.list.d/network:messaging:zeromq:release-draft.list curl -fsSL https://download.opensuse.org/repositories/network:messaging:zeromq:release-draft/xUbuntu_20.04/Release.key | gpg --dearmor | sudo tee /etc/apt/trusted.gpg.d/network_messaging_zeromq_release-draft.gpg > /dev/null sudo apt update sudo apt install libzmq3-dev That fixes the problem and the basic functions ZMQ LabVIEW library works.

-

Thank you for your response. I see this topic will be more and more interesting. So in relation to that Call Function Node doesn't find the library you suggest that libzmq cannot be found by ELF file (The question is: which one when I run vi in LabVIEW ide? just ./labview ?). But ok, not best but "a test" will be to check if the default loader can find dynamically load library (libzmq) which is used by the wrapper (lvzmq64.so) /usr/local/natinst/LabVIEW-2020-64/vi.lib/addons/zeromq$ ldd lvzmq64.so linux-vdso.so.1 (0x00007fffac9f1000) libzmq.so.5 => /lib/x86_64-linux-gnu/libzmq.so.5 (0x00007f3034e3e000) liblvrt.so.20.0 => /usr/local/lib64/liblvrt.so.20.0 (0x00007f303315a000) libc.so.6 => /lib/x86_64-linux-gnu/libc.so.6 (0x00007f3032f68000) ... so we are sure that it could be found (we know that it could be found in ld-cache because we checked it with ldconfig in previus post). However, that doesn't mean that EFL file can find it, because NODEFLIB flag could prevent that. *I have checked if ./labview has set this flag, but no. No response - it's off. But as I wrote before I am not sure if this is a real caller of wrapper library. $ readelf -d ./labview | grep NODEFLIB Another option where EFL file will look for the library is LD_LIBRARY_PATH and RPATH / RUNPATH. Changing LD_LIBRARY_PATH is not good practice but I have to checked it: export LD_LIBRARY_PATH=/lib/x86_64-linux-gnu/ which looks silly, doesn't change anything but I feel better that I've checked all ideas. RPATH and RUNPATH are set on compilation porcess, so I cannot change them easly. At this point, I cant see any problem that libzmq cannot be find as a resource. I think the issue is in wrapper itselfs, what is shown by this simple c app test.

-

Hello, I'm tring to make zmq package (https://sourceforge.net/projects/labview-zmq/) work on Linux Ubuntu 20.04. VIs api in this package relates on shared library creating in c and are builded for Windows but not for Linux. However we can find sources as well as a few tips how to build this library. $ ls bonzai.c debug.c makefile rename_calls.vi win32 zmq-errors.txt bonzai.h debug.h parse_errnos.py rename_lib2.vi win64 zmq_labview.c where zmq_labview.c is our main source file which could be build with makefile. As a source of knowledge I used Brandon Jones post on forum about how to build this package for NI Linux RT: https://sourceforge.net/p/labview-zmq/discussion/general/thread/d5d0b49987/ However, after many hours spend I sill getting error 13 when I tring to call this library from LabVIEW. Following steps show what I have tried, however in every step I could make a mistake as I'm not regular C programmer. ___________________________________________________________________________________ The first step is to check if two librarys which are needed by zmq_labview.c are avaiable in system: libzmq.so $ ldconfig -p | grep libzmq.so libzmq.so.5 (libc6,x86-64) => /lib/x86_64-linux-gnu/libzmq.so.5 libzmq.so (libc6,x86-64) => /lib/x86_64-linux-gnu/libzmq.so liblvrt.so (I dont undestant why its needed as its not included in zmq_labview.c but its used in makefile) $ ldconfig -p | grep liblvrt.so liblvrt.so.20.0 (libc6,x86-64) => /usr/local/lib64/liblvrt.so.20.0 liblvrt.so.15.0 (libc6) => /usr/local/lib/liblvrt.so.15.0 liblvrt.so (libc6,x86-64) => /usr/local/lib64/liblvrt.so NOTE: this output is from system where I didn't modyfied /etc/ld.so.conf.d. I have tired to add new file with paths to liblvrt.so as Brandon Jones describes, but I didn't recognized any difference. Next step is to modify source, so I set: #define LVALIGNMENT 8 and pthread_t thread; And then makefile modyfications are needed. I have simply removed all windows realted stuff and thats a result: # LVZMQ GNU-MAKE BUILD SCRIPT # for both Windows and Linux targets SRC = zmq_labview.c # LINUX BUILD RULES # omg so much simpler! LABVIEW = /usr/local/natinst/LabVIEW-2020-64 LDFLAGS = -L $(LABVIEW) -L /lib/x86_64-linux-gnu/ CFLAGS = -Wall -O3 -fpic -I $(LABVIEW)/cintools -I $(LABVIEW) LDLIBS = -lzmq -llvrt ifdef DEBUG CFLAGS += -DDEBUG endif all : lvzmq64.so # copy the product to the labview directory @cp $< $(LABVIEW)/vi.lib/addons/zeromq # Linux shared-library target lvzmq64.so : $(SRC) $(CC) -shared -o $@ $^ $(CFLAGS) $(LDFLAGS) $(LDLIBS) running make gives this results: In file included from bonzai.h:29, from zmq_labview.c:12: bonzai.c: In function ‘bonzai_grow_leaf’: bonzai.c:74:2: warning: this ‘for’ clause does not guard... [-Wmisleading-indentation] 74 | for ( i = 0; i < tree->n; ++i ); | ^~~ bonzai.c:76:3: note: ...this statement, but the latter is misleadingly indented as if it were guarded by the ‘for’ 76 | if (( t = tree->elem[i] ) && ( t->id == x )) | ^~ zmq_labview.c: In function ‘lvzmq_close’: zmq_labview.c:108:11: warning: variable ‘i’ set but not used [-Wunused-but-set-variable] 108 | int ret, i; void *sock; | ^ zmq_labview.c: In function ‘lvzmq_ctx_create_reserve’: zmq_labview.c:223:27: warning: cast to pointer from integer of different size [-Wint-to-pointer-cast] 223 | *pinstdata = bonzai_init(( void* )ninits ); | ^ zmq_labview.c: In function ‘lvzmq_send’: zmq_labview.c:485:25: warning: implicit declaration of function ‘zmq_msg_set_group’; did you mean ‘zmq_msg_set’? [-Wimplicit-function-declaration] 485 | if ( group && *group ) zmq_msg_set_group( &msg, group ); | ^~~~~~~~~~~~~~~~~ | zmq_msg_set zmq_labview.c: In function ‘lvzmq_receiver_thread’: zmq_labview.c:605:11: warning: variable ‘err’ set but not used [-Wunused-but-set-variable] 605 | int ret, err; | ^~~ zmq_labview.c: In function ‘lvzmq_join’: zmq_labview.c:860:8: warning: implicit declaration of function ‘zmq_join’; did you mean ‘lvzmq_join’? [-Wimplicit-function-declaration] 860 | ret = zmq_join( s->sock, group ); | ^~~~~~~~ | lvzmq_join zmq_labview.c: In function ‘lvzmq_leave’: zmq_labview.c:868:8: warning: implicit declaration of function ‘zmq_leave’; did you mean ‘lvzmq_leave’? [-Wimplicit-function-declaration] 868 | ret = zmq_leave( s->sock, group ); | ^~~~~~~~~ | lvzmq_leave so there are several warrnings, but the library is build and now I can test VIs which will use lvzmq64.so but first library call with finish with error 13. At this point, I tried to figure out how the Call Library Function is working and how to reproduce its task with c code, so I will get more info about the problem. The library is buit without .h file so in case of c call we need to use extern: #include <stdio.h> extern int lvzmq_ctx_create( int, int); //first function to call from labview to create context of zmq connection int main(){ printf("Test start\n"); int a; int b; lvzmq_ctx_create( a, b); return 0; } gcc compilation of this test gives an output: gcc test.c -L/home/user/Desktop/Lukas-Linux-folders/shared2/ -llvzmq64 /usr/bin/ld: /home/user/Desktop/Lukas-Linux-folders/shared2//liblvzmq64.so: undefined reference to `zmq_leave' /usr/bin/ld: /home/user/Desktop/Lukas-Linux-folders/shared2//liblvzmq64.so: undefined reference to `zmq_join' /usr/bin/ld: /home/user/Desktop/Lukas-Linux-folders/shared2//liblvzmq64.so: undefined reference to `zmq_msg_set_group' collect2: error: ld returned 1 exit status ok, so I got this error. It looks similar to warrnings reported by compiler when I build shared library. Now I stuck, because how it possible that those function calls are wrong, as its working on windows? Maybe the zmq package on Ubuntu doesn't contain those functions? Or I made a mistake when I build library. Any hint what to check next will be appreciated.

-

This is a nice improvement. Instead of configuring an additional c app in systemd file, its content can be run in the handler. The minimal wrapper code can be even more straightforward: void handler(int signum) { int fd; char * myfifo = "/tmp/LabVIEWCrossCommunication"; fd = open(myfifo,O_WRONLY); if(fd==-1) { printf("Error opening file: %s\n", strerror(errno)); } else { printf("Sending Close cmd to LabVIEWCrossCommunication \n"); write(fd, "Close", sizeof("Close")); close(fd); } unlink(myfifo); sleep(2); printf("Done\n"); } int main() { // printf("PID : %d\n", getpid()); //test with: kill -s SIGTERM pid signal(SIGTERM, handler); SharedLibEntryPoint(); return 0; } Thank you for your suggestion.

-

Thank you James, sending logs to Linux journal is easy thanks to pipes. Since I have not found any way to get any of Linux signal in my application I decided to open named pipe (Linux fifo) and read from it. Simple C application writes to the same pipe when service needs to be stopped. That makes possible to shutdown all LabVIEW modules correctly.

-

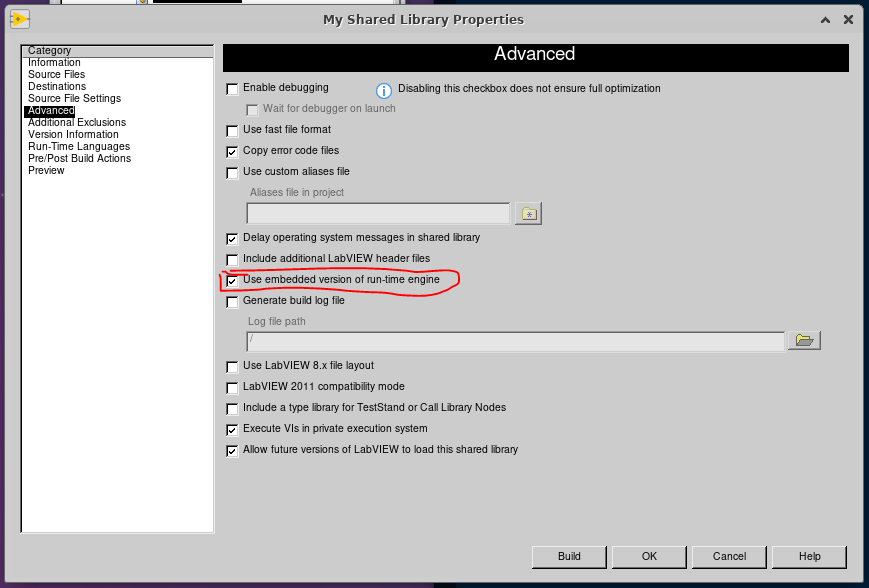

I'm trying to run LabVIEW application as a Linux service. To do that, I need to build the application without a user interface. Its possible and documented here: https://knowledge.ni.com/KnowledgeArticleDetails?id=kA00Z0000019RYlSAM&l=pl-PL However, if I will build an application which uses Python Nodes functions, it will crash with an unknown cpp error - so it's not supported or it's a LabVIEW bug. I can imagine that function is not supported - if by choosing "embedded version of the run-time engine" we are choosing to use the run-time engine which is used in Industrial Controller or cRIO . That makes sense because the feature of calling python code is not supported for targets like Industrial Controller. My question is what that feature do? What is the embedded version of the run-time engine (which target we can use)? crosspost : https://forums.ni.com/t5/Linux-Users/Embedded-version-of-run-time-engine-Python-Node/td-p/4240963

-

- 1

-

-

Hi, my challenge is to run our LabVIEW application as a Linux service. To achieve that, the systemd file needs to be created which defines execution files for starting and stopping the service. I have already look over the web to find some clues about this topic, however some knowledge is still missing and its related to how LabVIEW build shared library can interact with system. To explain it clearly I present what I have already done. Most services are running without a user interface, so the first task was to create a start execution file (Linux exe). I used this guide (https://knowledge.ni.com/KnowledgeArticleDetails?id=kA00Z0000019RYlSAM&l=pl-PL) to build our application as a shared library (so no user interface is used) and simple c program to launch it. It works, the application can be run from command line without UI. Similar command can be used in systemd file to define start of service ExecStart=/home/user/Desktop/MyAppNoUI-build/myappstart It also works. The service can be started and stopped. However, the stop function wasn’t defined so Linux sent KillSignal and the application was killed. I think it's not safe, I don't know what happened with all those open references etc. but I’m sure that I don't have any log from the application. So the first question is how to send the signal/message to the LabVIEW app? There is a possibility to specify the execution file which will be triggered on service stop, so this can be used. I have found - very simple - idea to trigger a c program which will create an empty file named “close” in the LabVIEW app directory. LabVIEW app checks periodically the directory and will trigger shutdown case when “close” would be found. This is a working solution, but I’m not sure if it's the best one. Next question is related to servicectl log access. It's very easy to use it in C (all printf functions are redirected to that log when the app is run as a service). However I don't know if it’s possible to do it with the LabVIEW app. I wonder if someone already done similar case so he can share ideas with us.

-

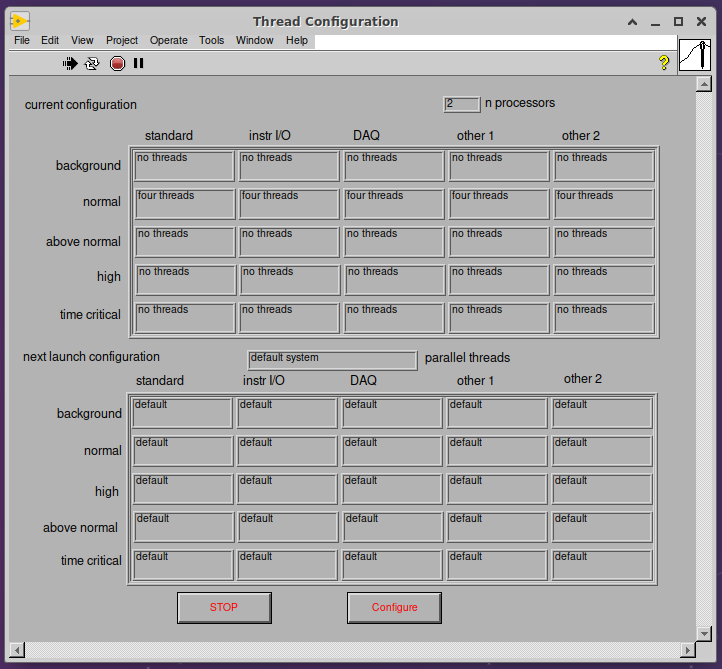

Thank you for your responses. If we made any configuration using Thread Configuration.VI then labview.ini will be changed i.e.: ESys.Normal=1 ESys.StdNParallel=-1 I haven't tried to copy those settings to the app.ini file yet. I think I need to figure out if the luck of other Execution Priority (fewer threads) could have an impact on performance. I have tried to reduce the number of threads for windows - to copy the configuration which was shown for Linux - but with that configuration, LabVIEW freezes at luncher.

-

Hello, I have noticed the difference in performance for the same application built on Windows and Linux (Ubuntu). Small differences could be understood but it looks like my app runs much slower on Ubuntu, so I tried to find any information what is that difference. I have checked the process created by the application in system performance and that's the first surprise: on widows I have 44 threads, on Linux 12 only. So it leads to question - is the parallel execution works on Linux ? I have tied to search the web to find any information related to how the application builder works but with no success. I would be grateful for any link or document describing that topic. edit: 44 thraeds on windows couled be expected when we have PC with 2 cores (2*20 + 4) according to https://knowledge.ni.com/KnowledgeArticleDetails?id=kA00Z000000PARmSAO&l=pl-PL On Linux, running the LabVIEW 20XX\vi.lib\Utility\sysinfo.llb\threadconfig.vi. will show us that: so the normal prioriti is used only (checked on Ubuntu and OPENsuse).

-

I'm using LabVIEW python nodes to call a python script, which creates an instance of OPC Server class. def initServer(url): server = Server() server.set_endpoint(url) ... The Server object cannot be serialized to JSON as well as cannot be pickled (TypeError: cannot pickle '_thread.RLock' object), so I can hardly see the way how to transfer Server object to LabVIEW. In that case I managed to store Server as a global variable in python script. This solutions works - I can call functions (ex. start/stop running) that simply use a global Server object. However, this solution is not secure - because if I lost the python session (due to the LabVIEW issue), I have no access to my Server. That leads to the question: Is there any more secure way to handle that?

-

LabVIEW CLFN - pass bool pointer to function and change it value

Łukasz replied to Łukasz's topic in Calling External Code

Thanks for the answers, the dll which wraps those functions is the easiest way to get it working. However, I was simply curious if there is any other possibility. - to clarify a running variable - it's a flag that specifies if the server should continue its process. If you pass false to UA_Server_run, then it will not start. Strange, but works. I haven't found UA_Server_stop function yet. -

Hello, I'm trying to move the example of library use from C to LabVIEW. The function is C looks like that: static volatile UA_Boolean running = true; static void stopHandler(int sig) { running = false; } int main(void) { ... UA_StatusCode retval = UA_Server_run(server, &running); ... the code goes to the Server_run function and stops here as long as the variable running is true. In C stopHandler will change that and the program can finish. How we can transfer this functionality to LabVIEW? What should be connected as a second parameter to the CLF node function?

-

Hi, I wonder if anyone have created an app for customer using the web VI hosted on SystemLink Cloud. I find there is a lot of fun playing with that tool but I am not sure if its ready to offer solutions based on this technology. I tried it to create a Testing Process Dashboard , where the Teststand sends result via tags - it's stable, looks ok but during development I found many gaps in documentation. However it's just a dashboard. I can see many possibilities if the Web VI, LabVIEW app, maybe web service are used together, but its hard to find any industrial project description on NI webpages. Can you share your experience with me?

-

Hello, I wonder why my CAN Arb. ID is different when I'm using NI MAX Bus monitor (1700E701) and ncReadNetMult.vi (3700E701). The system is working with extended ID.

-

There is a ASCII COMTRADE file. 20161014_081348_870.zip

-

Thank you for your response, i already had read Compact Rio Dev Guide and also we will contact NI support. I just want to be well prepared before project starts. I like to collect any tip, which could be usefull at planning state.

-

Hi, i'am looking for knowladge about project design pattern for control application with more then 1 cRIO controller. My task is to choose architecture, so i like to know which communication way is common use, which designe patterns are good to build main VIs, general good practice etc. The project is a production line with lots of servos, CVS controler with vision algorithm, and desktop application as a SCADA system. At this point, i think is good to use Simple Messaging Library to send communication in system and Current Value Table to sending data. Also i will use "standard" Queued State Machine Design Pattern on each device. I will be gratefull for any source of knowladge about how to program similar systems. Best wishes, Lukas