-

Posts

299 -

Joined

-

Last visited

-

Days Won

1

Content Type

Profiles

Forums

Downloads

Gallery

Posts posted by Thang Nguyen

-

-

Hi,

In current picture control, the origin start at top left corner and it's positive direction go down to the bottom. I would like to use picture control to draw map for my robot project, but I would like to display as a normal coordinator system which mean vertical positive direction is go up and origin start at bottom left corner. I am trying to shift the origin and swap all y value. I wonder if there is better way than this.

Regards,

Thang Nguyen

-

I do use SetValVariant to set LabView objects to predefined object reference variables in TestStand. It works! I don't do this within LabView but in TestStand itself. But since both use the TS API it should make no difference. I don't know why OP's example does not work, maybe because he also tries to create the object reference variable per API. I use TestStand / LabView 2012.

Thomas,

Could you please take a screenshot of the part where you do this in TS?

Regards,

Thang Nguyen

-

I am using TestStand 2010 so if this information is not correct for later version, please help me remove this topic.

In TestStand, when there is a step does not run because of previous condition step like "If", the status of that step will be left as empty. This returns a clear visual affect, in debugging, that this step has not run. But if I have a condition step and another step under this condition. If in the first interval this step ran and in the second interval this step didn't run, it still keep the status from the first run interval.If I just put a break point at the begin of the loop and click play instead of go through each step, I will think that these step ran in the second interval. Should it be better if there is a flag or something indicates that this step did not run at all?

Regards,

Thang Nguyen

-

@ininitenothing: I would like to fit the plane not the boundary. Thanks.

-

@infinitenothing: Thanks for your reply.

One of the issue is the surface can be tilt, so I cannot use the average value.

I also have the case the cylinder diameter is greater than the range of the laser scan which I need to do 2 scan. In this case, I have to fit two half circle before I can stitch them together. To generalize my question, I am looking for a method to fit a 3D surface with some certain shape.

-

I am sorry, I was not clear but I mean a 3D scan of circular surface, not a circular fit.

-

Hi,

I have data from laser scan of a circular surface. I converted data to image and using circular edge detection to mask out the background. What I like to do next is to fit the surface then subtract my original data from it. I am not sure if there is any function I can use to fit specifically in the boundary of the object only. Please let me know what function that I should use.

Thanks you.

-

What is your email, Lisa?

Regards,

-

@Mikael: Basicly what you use is a name queue, am I correct? That's how you get the reference to another object. Thank you very much for your time building the example code

@Shoneill: Thanks for your advice. I will think a way to combine user event in LVOOP. There are some great feature I still want to use from LVOOP.

-

Hi,

I need advice on how to exchange messages between 2 classes or 2 objects. So far I am using LVOOP mostly because of data encapsulation and inheritance feature.

Now I need communication between 2 objects A and B running parallel. Each object can send message to another. I can send message one way by using composition relationship. I put one class inside another class cluster, for example B inside A cluster. Then later from inside class A, I can use class B reference to send message to process of class B. But I don't know how to send message back from B to A. Is there any design pattern about this? Or is there any example? I can do this without using class by using name queue but I would like to learn how to do this with LVOOP.

I read about actor framework already but I don't want to use it now seam it's a little bit complicated for my project.

Thank you for your time reading and answering my question!

Thang Nguyen

-

You are right. I think the problem is myself, I need to identify clearly what I want. Currently, I am confuse that if I want deterministic or not.

-

@Crossrulz: I have 3 array of doubles (640 elements each from a line scan). I guess I can use single process shared variable single element with another counter to tell if this is the latest data or not. How do you think?

Edit: Sorry for my brainstorm idea. I forgot that I don't want it polling. I want the blocking feature.

-

Hi,

I would like to ask which method should I use for transferring latest data between determinism process. I don't want to use single process shared variable with RT FIFO enable since it will polling data. I don't want to use the RT FIFO function because I cannot send the latest value. Queue is not determinism. I am not sure if Notify is determinism or not. Anyone with experience about this?

Regards,

Thang Nguyen

-

Thanks Shaun, I will read through it.

-

Shaun,

I know NI will not run on Raspberry Pi, I am thinking about Ethernet communication. The link your provided does not work. Could you please edit it?

Thank you for your help.

NI software doesn't run on Raspberry Pi but it's fairly easy to set up an IP camera with the motion service.

-

Hi,

I have some experience with image processing using NI IMAQdx and some standard cameras and line scans, but I don't have much knowledge about the camera interface. Now I would like to do some home projects which using NI IMAQdx but with lower budget camera with decent quality. I found some wireless camera on eBay but the quality is not really good (I think so). There is just a new Raspberry PI camera on the market (http://www.raspberrypi.org/product/camera-module/)

I am collecting information on how to using this camera. I know that I have to use a Raspberry PI model B to connect to this camera but it only provides the features to monitor camera directly. Now I wonder how hard it is to make a IP camera with this Raspberry Pi with camera. I am not an expert in linux as well as C program but I am wiling to learn. Anyone can give me some idea what and where I need to look for. Or another camera option?

Thanks!

-

You can go to ni.com web site and choose the product you want. The basic one is an analog output module with a Ethernet compactDAQ chassis.

-

Pallen,

It turns out my censors are fired by my coworker. We ordered a new one and it works as it suppose to be.

Thanks all!

-

Hi,

I would like to ask if any have experiment with Omega load cell LCMFL series? By some reasons, I cannot get any response from the load cell. So I need help.

In my project I have a load cell LCMFL 20N connect with NI 9237 card. I set it up with full bridge (verify with customer service), internal, 5 V excitation. The scale is 10N 1mV/V. I cannot get any response from it.

Then I tried to connect it with a 5VDC power supply and use multimeter to measure but the response signal is not changed either. So I wonder if I do anything wrong with the wiring or not.

Regards,

Thang Nguyen

-

Max,

I use RMS VI to calculate and get a reasonable value compare between 2 sensor, so now they are good. The AC thing was quite make me confused.

Thank you so much for your help!

Regards,

Thang Nguyen

-

Max,

I tried with RSE but it didn't work.

Great ! one of the problem is solved...

! one of the problem is solved...for the Fluke I don't think that the output is in AC... I suppose that is in DC and with the data you wrote 0,4V for each Ampere of measurement (e.g. if the reading is 2A the output should be 0.8V) so I think that the same connection of the transducer with a fullscale limited at 2V will be sufficient...

let me know

Max

-

Max,

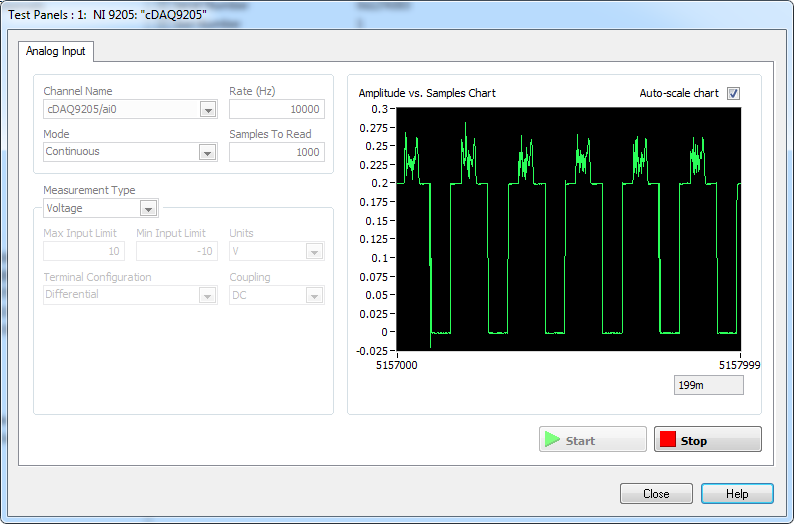

I tried with RSE connection and it works. Thank you very much!

Now with the Fluke clamp. I think it returns AC voltage. Do you have any experience with this?

Regards,

Thang Nguyen

-

Max,

Yes, it's a differential input.

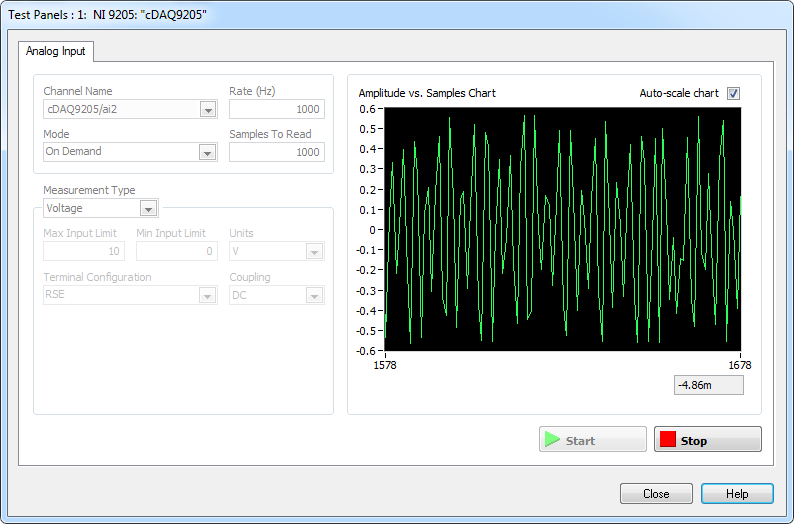

Since I have just accessed to a scope, and I tested with my current lamp + an industry fan, I got a really good DC signal from transducer. But from Max, I got the same level of peak but the signal still goes to zero as in my first picture. Somehow I get a noise from my card.

Regards,

Thang Nguyen -

What is the most effective method to change the coordinator on picture control?

in User Interface

Posted

Thanks Chris and Yair. I decided to swap the Y to keep it simple . At the beginning I miscalculated the offset for origin, but I have correct value now.

. At the beginning I miscalculated the offset for origin, but I have correct value now.