Search the Community

Showing results for tags 'configuration'.

-

openG Configuration Library, error post build

nrosenberg posted a topic in OpenG General Discussions

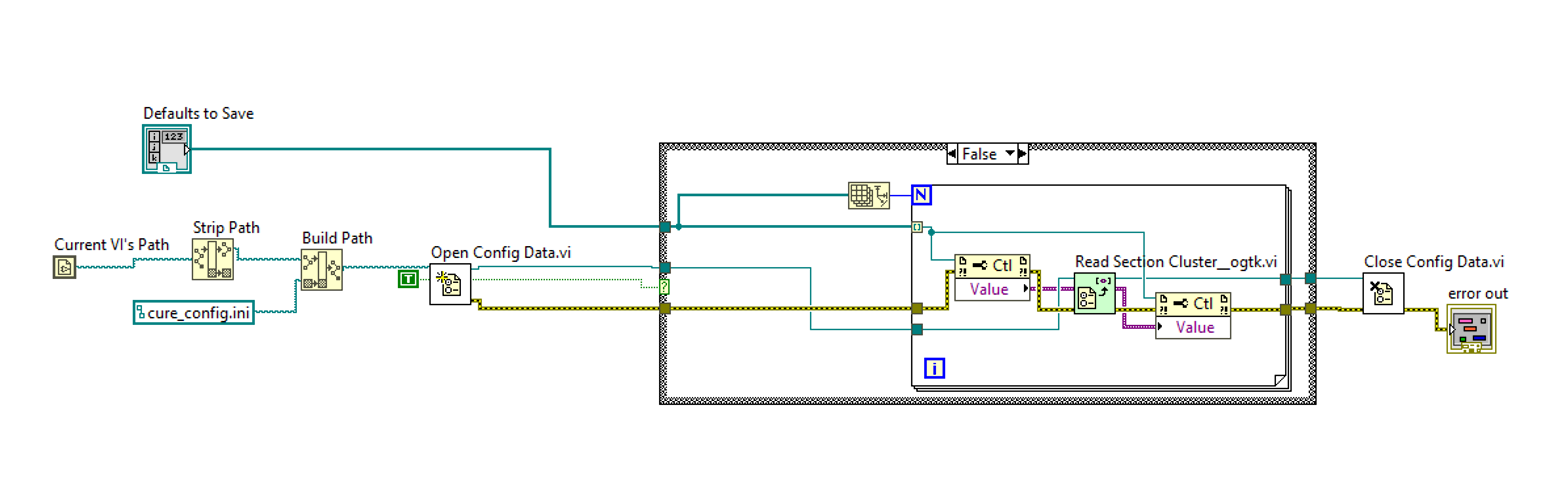

Hello All! First post here, please go easy and I look forward to learning from you all! I have a vi that is using the open g configuration library to save and load a number of controls. More precisely, I have 1 cluster of 3 numerics, and 3 separate numerics. I have all my code working wonderfully before I compile it, but once I compile it I get the following error when I try to load from the file: Get Queue Status in NI_LVConfig.lvlib:Get File Path.vi->NI_LVConfig.lvlib:Close Config Data.vi Additionally, while I have the 'Create File if necessary' input wired True, the vi never creates the file. Again, this all works pre-compiled, but fails in the compiled code. I've attached some screenshots of the code in question, please let me know if I can provide further info. Thanks, Nate -

Dear All, I'm new to this forum and I'm really glad I became a member. I am currently in the phase of designing a simple program which can control all the DAQmx channels using a configuration file (.ini) which is capable of change voltage range during mid-simulation. At the moment my .ini file reads as follows: [AO Channel 1] Name = T2 Physical Channel = cDAQ1Mod1/ao0 Max Value = 10 Min Value = 0 [AO Channel 2] Name = T3 Physical Channel = cDAQ1Mod1/ao1 Max Value = 10 Min Value = 0 [AO Channel 1] Name = T2 Physical Channel = cDAQ1Mod1/ao0 Max Value = 5 Min Value = 0 [AO Channel 2] Name = T3 Physical Channel = cDAQ1Mod1/ao1 Max Value = 10 Min Value = 0 My LabVIEW VI for the .ini script is attached. I'm relatively new to using configuration file functions and I don't really understand where "Get Key Names" section should be wired to. I have placed a constant on it for now which reads the "AO Channel 1" but how can I get it to read all the channels in the .ini file. I am welcome to all suggestions here, I just want to make sure that I don't cause any problems to any of the channels and use best practice methods. All constructive criticism welcome! Thank you. Read Configuration (INI) File (1).vi

- 3 replies

-

- config

- configuration

-

(and 3 more)

Tagged with:

-

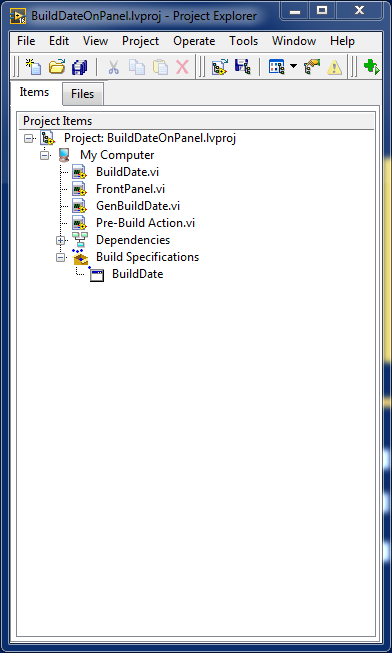

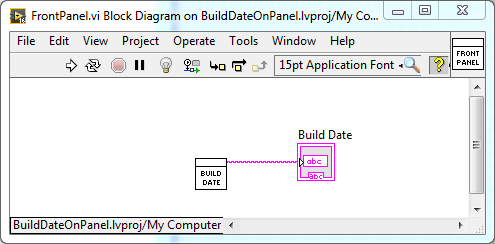

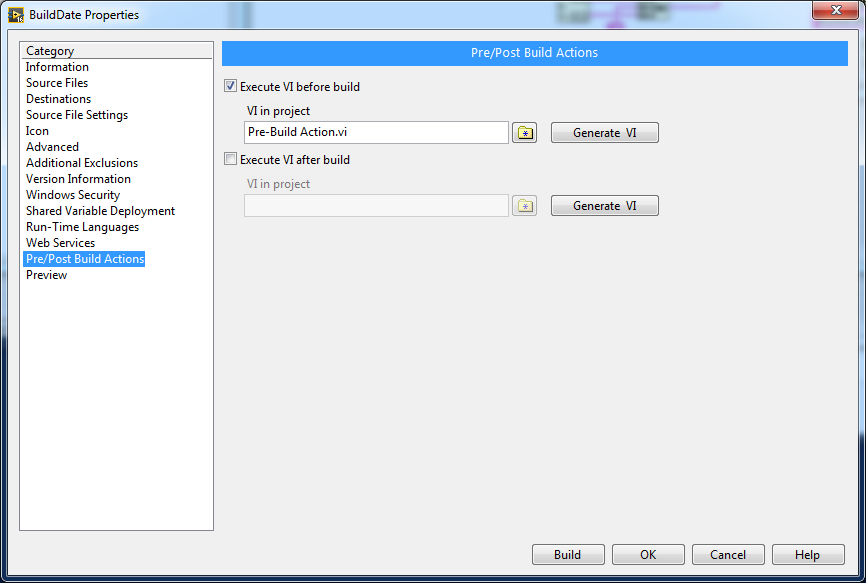

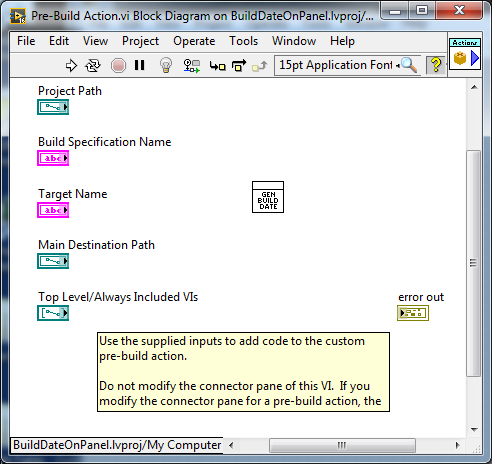

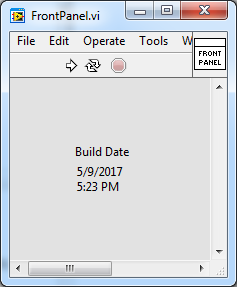

So for a while, I have wanted a good way of identifying my builds and one way is to add build date to the front panel. Typically I had done this manually, I have searched for a good solution for automating this but, but typically the answer is very obfuscated. Then one day I had a thought, I could use VI scripting to generate a VI holding a constant and in a way use it as a pre-processor to make things happen. I'll provide a rough outline and a project of how I made things work. And who knows maybe someone has an even better solution. I suppose it was kinda obvious that this could be done, now that I think of it. I think lv scripting was introduced in 2012 and is needed for this example. First Create A VI that generates a constant via LV script. Use it in your Top Level VI or wherever you would like the compile time constant to be visible. Generate a A Pre-build Action.vi that calls your VI generator. Now you can have compile time constants that are up to date! I included an example project let me know if the same thing works for you. BuildDateOnPanel Ver12.zip

- 8 replies

-

- configuration

- lvscripting

-

(and 1 more)

Tagged with:

-

Hello again LAVAG, I'm currently feeling the pain of propagating changes to multiple, slightly different configuration files, and am searching for a way to make things a bit more palatable. To give some background, my application is configuration driven in that it exists to control a machine which has many subsystems, each of which can be configured in different ways to produce different results. Some of these subsystems include: DAQ, Actuator Control, Safety Limit Monitoring, CAN communication, and Calculation/Calibration. The current configuration scheme is that I have one main configuration file, and several sub-system configuration files. The main file is essentially an array of classes flattened to binary, while the sub-system files are human readable (INI) files that can be loaded/saved from the main file editor UI. It is important to note that this scheme is not dynamic; or to put it another way, the main file does not update automatically from the sub-files, so any changes to sub-files must be manually reloaded in the main file editor UI. The problem in this comes from the fact that we periodically update calibration values in one sub-config file, and we maintain safety limits for each DUT (device under test) in another sub-file. This means that we have many configurations, all of which must me updated when a calibration changes. I am currently brainstorming ways to ease this burden, while making sure that the latest calibration values get propagated to each configuration, and was hoping that someone on LAVAG had experience with this type of calibration management. My current idea has several steps: Rework the main configuration file to be human readable. Store file paths to sub-files in the main file instead of storing the sub-file data. Load the sub-file data when the main file is loaded. Develop a set of default sub-files which contain basic configurations and calibration data. Set up the main file loading routine to pull from the default sub-files unless a unique sub-file is not specified. Store only the parameters that differ from the default values in the unique subfile. Load the default values first, then overwrite only the unique values. This would work similarly to the way that LabVIEW.ini works. If you do not specify a key, LabVIEW uses its internal default. This has two advantages: Allows calibration and other base configuration changes to easily propagate through to other configs. Allows the user to quickly identify configuration differences. Steps 4 and 5 are really the crux of making life easier, since they allow global changes to all configurations. One thing to note here is that these configurations are stored in an SVN repository to allow versioning and recovery if something breaks. So my questions to LAVAG are: Has anyone ever encountered a need to propagate configuration changes like this? How did you handle it? Does the proposal above seem feasible? What gotchas have I missed that will make my life miserable in the future? Thanks in advance everyone! Drew

- 25 replies

-

- configuration

- architecture

-

(and 3 more)

Tagged with:

-

Hello to all. I would like to know hoe can open my VI with the same configuration. I mean with every indicators, controls, graphs... are equal than when Labview was closed the las time. Is it that possible? I am asking this because I am developing a vision application with vision and motion toolkit. And a ROI is changed every time when I run again Labview in the same position of display. Thanks a lot.