Search the Community

Showing results for tags 'cdaq'.

-

I have a LabVIEW program, which when operating with simulated input data is blazing fast during mock-up. As soon as I hooked into a real cDAQ on Windows, however, the update speed fell off to 4 seconds. That's awful slow. I don't really have a whole lot of channels. I have read tasks for Volts of maybe 5 channels, write tasks for both On./Off for maybe 10 channels (simultaneous) and write tasks for 4-20mA of only 5 channels. How may I improve on that? Is it maybe a priority issue in Windows or to do with USB? What? How to improve? Thanks in advance.

-

Hi, I have contacted NI sales services but it's a great frustration as usual, so I will try to get some support here Basically for a project I need 2 CAN ports and I decided to go with XNET and Compact DAQ. I have 2 solutions I try to choose from: Solution 1 --> One 4-slot chassis with 2 NI-9862 modules (one port per module) Solution 2 --> One 1-slot chassis with 1 NI-9860 module (this module has 2 ports) I am confident that solution 1 will work well since I already had a project in the past with one 4-slot chassis (cDAQ-9174) and one NI-9862 module. But going with solution 2 will allow me to cut cost significantly. I just want to make sure it will be absolutely seamless and transparent for the software. Does anybody have experience with the NI-9860? Can it be considered as the equivalent of 2x NI-9862 as far as the software is concerned (LabVIEW driver) or does it remove some performance/flexibility/other? Thanks!

-

Lets pretend I wanted to simulate a solar panel using a cDAQ, a programmable power supply and a light sensor. Id have to measure the voltage from the light sensor and the PSUs current, use those values to find the respective operating point on my light/voltage/current-curve and update the PSUs settings. Lets also say I wanted to do this for multiple systems in parallel, all connected to 1 analog input and 1 analog output module in 1 cDAQ. What would be the best way to achieve the quickest response time? Simply reading and writing single samples seams to be pretty slow (though I can encapsulate everything neatly this way). Is there a better way?

-

Hello, I've been struggling with this problem for months now... I want to use a cDAQ9171+NI-9234 with an Advantech PC (AIMB-580). I have 3 computers like this and all with the same problem. I plug the USB cDAQ-9171, Windows detect the device and loads the proper driver (cDAQ-9171), it is displayed in MAX but self-test or reset always fails with error. At the same time, NI Devive Loader service hangs up. If I try to restart or stop this service it cannot complete the operation, the only way to finish this operation is to unplug the usb cable from the PC, then the service restarts correctly. Additionally the windows' event logger shows the next error message: or In one PC I re-installed Windows, installed DAQmx 14 and the problem was still there, this is with a Windows fresh-install... After this, I removed DAQmx 14 and installed DAQmx 9.8 (supplied in CD) and the it worked!!! I upgraded to DAQmx 9.9 and it was still working, so I stoped there as it was all I needed (9.8 has some bugs with NI-9234 that 9.9 solves). One thing to note, when it works, Windows first install cDAQ-9171 driver, but then inmediatly it changes to USB flash firmware updater, after this it returns again to load cDAQ-9171 and detects the NI-9134. When it don't work it only installs the cDAQ-9171 and doesn't load anything more... I tried in a second PC to repeat the process, but I have been not able to repeat the success, only the fail... I get the same error every time I plug the USB and I have not idea of what else try... I have disabled UAC, cleared the MAX data, reinstall windows 2 times, tried with DAQmx 9.8, 9.9 and 14. Forced USB flash firmware updater as Windows driver, changed BIOS settings (disable hyper-threading, VT extensions, USB legacy, etc.). I am almost sure that it is some kind of weird incompatibility or similar, the thing is that NI device loader always hangs-up. In the next days I'm going to try to copy the same exact configuration of BIOS from the working PC, just to be sure. Any recommendation?

-

I am designing a new project and I need to know if I can get away with purchasing 2 9181 chassis instead of one 9188 chassis. I will be using a 9213 for thermocouple readings and a 9208 for 4-20mA current readings. The signals dont nee to be syncronized and will only have to read once a minute or so. My question is whether or not I can read the signals from both chassis at the same time through MAX and easily imput into a LabVIEW program. I am currently using a single 9188 to accomplish the same tasks at a different location but am trying to cut costs on the next project. The 9184 is not an option due to the software version I am running.

-

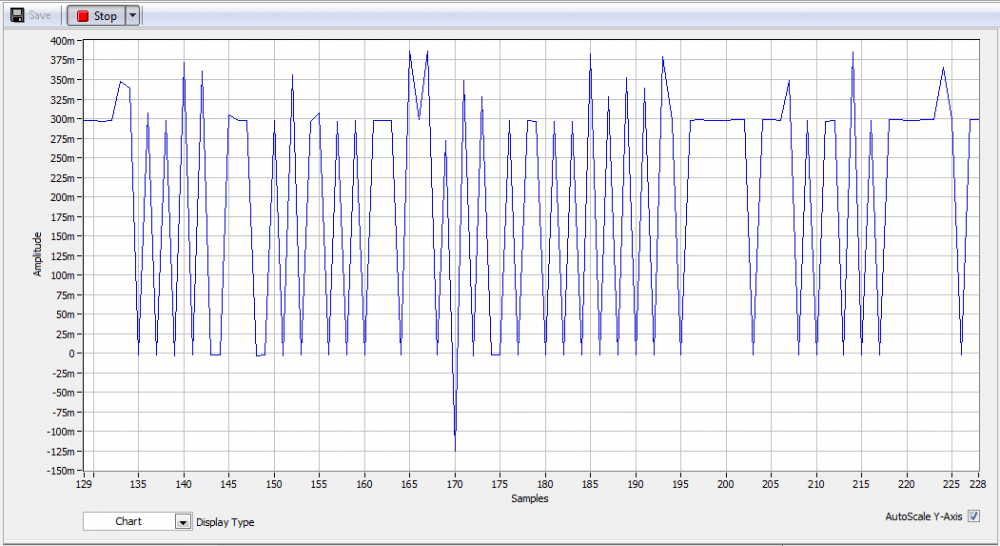

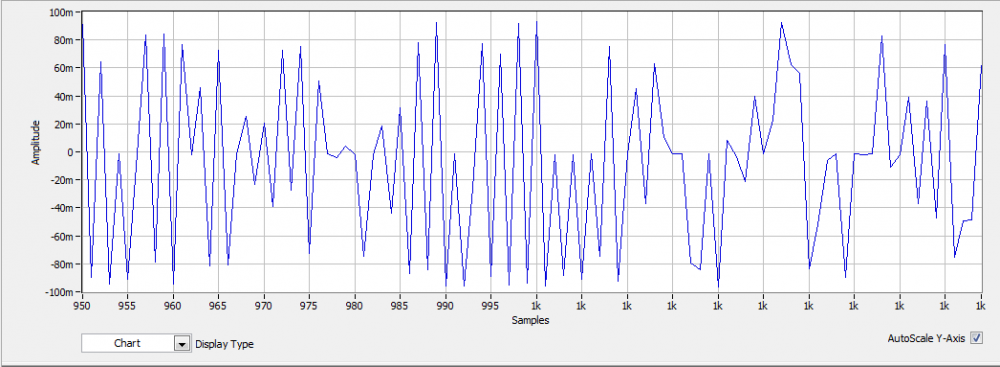

I am working on a project with requirement of measuring current. The system includes both the AC current transducer CR4211-15 (Input 0/15AAC, Output 0/10VDC) and a Fluke i5S (Input 0.01/5AAC, Output 400mV/A). I use cDAQ9184 with NI-9205. I tested with a light and using MAX to monitor the signal but the signal really noise from the AC transducer and clamp. Please take a look at the pics I attached which is the screenshot from MAX. I hope anyone with exp can give me a help. Thank you! Thang Nguyen

-

For years I have successfully used the Icron USB Ranger 2204 Cat 5 Extender with both cDAQ and SCXI. But now I have one very annoying issue. I only recently purchased some NI 9237 units for my pressure transucers. Those, and only those, modules don't seem to like being polled over the USB-to-Cat5 extenders which I have in both of my test cells. I have timing issues. Not with all of them all of the time. But with all of them some of the time and with some of them all of the time. I get that pop-up message that says not all of my channels have been read. Increasing the timeout even to ridiculous lengths helps not at all. The rest of the porgram works just fine so long as I do not assign a bridge channel. So, what gives? I can't go bringing my PC closer to the test setup because of safety reasons. We're a combustion lab. I don't want to have to be stringing out long wires all of the time because we're a test lab and those get set up, taken down, changed all around every week. It's a big issue. Can anybody recommend a USB extender other than the Icon which they have used with good success on the 9237 units? All that I am trying to read are finite samples, just two of those, and the speed doesn't matter much. I've already tried different speeds to no avail.

-

I'm needing two c-series Modules for the CompactDAQ. They are a GPS module and an accelerometer module. I know that S.E.A. sell a GPS c series module, but it is only compatible with cRIO, not cDAQ, obviously with the different interfaces. Does anyone know of any companies that sell GPS and accelerometer modules for the cDAQ? Thanks.

- 4 replies

-

- cdaq

- compactdaq

-

(and 2 more)

Tagged with: