Search the Community

Showing results for tags 'plc'.

-

LabVIEW 2016 Modbus Communication with a PLC Siemens SIMATIC ET 200SP Windows 7 Ultimate Hi, When I run my code it return error 66 at Read Holding Registers function. I ran this code as a VI on the development virtual machine and as a *.exe on real machine, but received the same error. Try in another computer and receive the same error. As PLC code was developer by other programmer I ask him if this communication was working on his machine, he showed me a LAbVIEW code running with Modbus communication with the same PLC. He was using a LabVIEW 2013 with old Modbus Library, but I had taken his code and ran on my PC with LV 2016 and receive the same error on MB Ethernet MAster Query Read Holding Registers(Poly).vi. Also generate an exe file and run on my real machine and still receiving error 66. In all scenarios I can ping PLC and receive answers, but cannot read or write any data with LabVIEW. First picture is my code with LV 2016 VIs. Second picture is error message. Third one is the other programmer code with old Modbus Library. On the first code, if I remove Read Holding Registers VI and connct wires directly or put a property node to set any property it runs without errors. If change this function for any other modbus function return error 66. Any idea what I am doing wrong? Thanks in advance! ni_support.zip Comunicação CLP.vi Main_MB_2.vi

-

I am assigned to refurbish an airflow instrument having six pressure sensors, four temp sensors, and six on/off outputs. By preference I would use all NI hardware, but this isn't going to be allowed. I'm being pushed toward installing an Allen Bradley PLC instead. I am aware of another, much more complicated liquid flow test stand which, so I'm informed, uses LabVIEW for SCADA on a Seimens PLC. This being the case, cannot I do likewise with Allen Bradley? Can I do it entirely in LabVIEW? Or is something like that always just LabVIEW sending trigger commands and receiving data from a free-standing program written in the PLC's own native SCADA? I'll be starting from scratch, with nothing yet purchased. I can purchase whatever I choose. I have perused a couple of PDFs of Allen Bradley ControlLogix programs, and at first glance, to me they look like a major pain. Unlike LabVIEW, almost nothing shows on any one screen. Nothing at all looked to have been nested into a subroutine. I liked ladder and highway diagrams quite well enough back in the 90's when printed out on D-size vellum. Then, at least, I could stand back and see the whole thing. The same thing seen only through a tiny window that you have to scroll up and down I'm not looking forward to learning at all. Thus my hope for a LabVIEW solution, rather than purchase and learn AB's Studio 5000. I'm an old dog, and this looks like a new trick to me.

-

Hello all, I recently was presented with the task of integrating a Mitsubishi PLC into our systems. After a good deal of googling, I think the best (maybe only) way to get the data out is going to be via OPC, thanks to their proprietary Melsoft protocol. If anyone else knows a better way, feel free to stop me here. Now, we are currently expanding our data generating capabilities (hence the PLC), and I have been thinking about rearchitecting the way we collect data from all over our facility to be more flexible. Since I may be required to use OPC anyways, I was considering using an OPC server to aggregate all of the facility data, and then redistribute to control rooms, historical logging, etc. To do this, we would need to integrate our cRIOs and operator PCs into the OPC environment as well. I don’t see OPC mentioned very often (in fact it returns 0 results on LAVAG), and a lot of the stuff I see these days seems to be more “roll your own” or lower level (raw TCP/UDP, 0MQ, Network Streams, Transport.lvlib etc.) rather than a monolithic abstracting bridge like OPC. Unfortunately, I won’t have time to roll my own in the near future, but LVRT supports supports OPC UA, so I could potentially integrate the cRIOs fairly easily. Unfortunately, I think I would have to use LabVIEW DSC (or datasockets...) to integrate the PCs. I would be very grateful if anyone has the experience to comment on the following or anything else related to using OPC. What are viable update rates for OPC tags? I will need at the very (very) least 250 ms update rates. Is OPC typically low latency (time from data generated to to client received)? Does anyone have a recommendation for a product (NI OPC, Kepware, etc.)? Is OPC still popular, or are there other options for data aggregation that would be better suited to a new application? What are the options for logging and alarming with OPC? What are the options for talking to OPC from LabVIEW? How robust are the OPC connections in regards to reconnecting if a wireless connection is temporarily lost? Thanks in advance!

-

Hi Guys, I'm with a trouble here. Recently we started to get our outdated temperature test cabinet to work, and the best way is to upgrade our PLC. But there cames 2 problems, the biggest is the budget, we do not have any money so we have to work with what we already have, and the second, i'm intern here and there is no one from automation to guide or help me. Now lets face the problem. PLC Allen Bradley micrologix 1100 cards: 1762-IQ16 and 1762-IQ8W6 My first thought is to use Labview to control the PLC, as HMI and data-logger without OPC server to simplify the instalation and cost. The communication: this is really where the problems begin. It will be done through Ethernet. I could not manage Ethernet/IP driver to work, nor pcc or CIP message... which is the best way to communicate? CIP Message, OPC, or any other i do not know? Do you guys see any problems to make a dataloger without OPC? Some things I have tryed Implementation of Common industrial Protocol (CIP) via EtherNet [EtherNet/IP (CIP)] https://lavag.org/topic/6104-industrial-ethernet-ethernetip/?page=1 Ethernet/IP Driver for Micrologix 1100 https://decibel.ni.com/content/docs/DOC-13024 EtherNet/IP Driver for Industrial Communication https://decibel.ni.com/content/docs/DOC-4065 Thanks for any help Ricardo PS. Originally posted at: https://decibel.ni.com/content/thread/47497

- 5 replies

-

- plc

- ethernet/ip

-

(and 3 more)

Tagged with:

-

Hi Guys, I'm with a trouble here. Recently we started to get our outdated temperature test cabinet to work, and the best way is to upgrade our PLC. But there cames 2 problems, the biggest is the budget, we do not have any money so we have to work with what we already have, and the second, i'm intern here and there is no one from automation to guide or help me. Now lets face the problem. PLC Allen Bradley micrologix 1100 cards: 1762-IQ16 and 1762-IQ8W6 My first thought is to use Labview to control the PLC, as HMI and data-logger without OPC server to simplify the instalation and cost. The communication: this is really where the problems begin. It will be done through Ethernet. I could not manage Ethernet/IP driver to work, nor pcc or CIP message... which is the best way to communicate? CIP Message, OPC, or any other i do not know? Do you guys see any problems to make a dataloger without OPC? Some things I have tryed Implementation of Common industrial Protocol (CIP) via EtherNet [EtherNet/IP (CIP)] https://lavag.org/topic/6104-industrial-ethernet-ethernetip/?page=1 Ethernet/IP Driver for Micrologix 1100 https://decibel.ni.com/content/docs/DOC-13024 EtherNet/IP Driver for Industrial Communication https://decibel.ni.com/content/docs/DOC-4065 Thanks for any help Ricardo PS. Originally posted at: https://decibel.ni.com/content/thread/47497

-

- plc

- ethernet/ip

-

(and 3 more)

Tagged with:

-

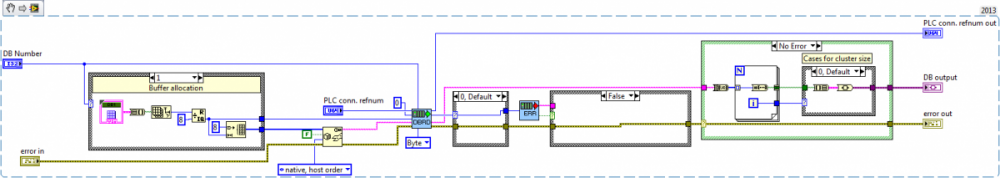

Hello, I've been using Snap7 library for a while in the client role, so I can communicate with SIEMENS PLCs There is specific LabVIEW info here: http://snap7.sourceforge.net/labview.html I can successfully use the Cli VIs to read/write from PLCs DBs (a DB is just a memory block). For reading I pre-allocate a buffer, but I'm not sure if I'm doing it properly. My main concern is about memory leakage, I don't know if the memory will be freed after the VI exits or it will not be freed as long as the VI is in memory. Attached is what I have just now for reading. I define a typedef for each DB, it is a cluster of booleans, and reserve memory according to the number of booleans, but always in multiple of 8 (I read only bytes). I request the data with the CliDBRead and after that I make some conversions to return the data in a variant that I later cast to the proper typedef. Can you tell me if this is the best way to do this? Thank you!

-

Hi everyone, I've got a problem that I'm desperately in need of assistance. The basic setup is that I've got a SLC5/05 Allan Bradley PLC system communication to a screen (HMI). I've thrown an ethernet switch in between the PLC and screen and everything continues to work correctly. I have then connected a CompactRIO to the switch, which has been setup to 'sniff' the PLC tag packets. This works successfully using the Industrial EtherNet/IP Communications LabVIEW Module. The problem I'm having is on a second set of hardware, where PLC tag reading works on 1 PLC, but not another. I am also physically using a different cRIO, but with the exact same hardware and cRIO image has been copied. The PLC hardware and firmware should also be the same as well. All IP addresses are the same for both systems, and the PLC can be pinged successfully. Actually, as far as I'm concerned it's a duplicate system in every way. I can also tell you that when I request for a PLC tag reading, I get the following error code -251723745. I've spoken to NI who say that this is not a generic LabVIEW error but relates to a PCCC status error whose code is 0xF0. This error is within range used to indicate Object Class Specific errors. However, I don't know enough about AB PLC systems to understand what this means. Is there anyone who can help me? Anyone with similar experiences or troubles with EtherNet/IP protocol using LabVIEW. Thanks. Brenton Lang

- 1 reply

-

- ethernet/ip

- plc

-

(and 2 more)

Tagged with: