-

Posts

955 -

Joined

-

Last visited

-

Days Won

34

Content Type

Profiles

Forums

Downloads

Gallery

Posts posted by Antoine Chalons

-

-

After installing the latest version with VIPM on my LabVIEW 2018 SP1 32 bit, every time I try to run LabVIEW, it crashes.

I deleted the folder C:\Program Files (x86)\National Instruments\LabVIEW 2018\project\UI Tools and then no more crash.

Any idea?

-

I think you find it all on NI's ftp website : http://download.ni.com/support/daq/pc/ni-daq/

-

I think you have to display the result of the threshold as an overlay on the original image, I guess this is what they do.

Have you checked at the examples in LabVIEW, I think there is one that does that.

Help > Find examples... > then search for threshold

-

Qualimatest is looking for a senior LabVIEW developer, see more here.

Edit : the job offer is only published on the french section of the website, if you select german or english, the site will say that there is no open position.

There are 2 open positions only one for a LabVIEW developer, though and only on the french page.

-

6 minutes ago, mthheitor said:

You are welcome, this llb is indispensable for scripting and can also help for UI management

-

20 minutes ago, Neil Pate said:

Totally off-topic, why would you "re-set" the session reference?

I don't have a good answer to that question so I'm not going to make up a bad one. It's completely unnecessary.

-

1

1

-

1

1

-

-

Here is an example of how I set the exposure time on a basler camera (Beat 4000-62km)

Hope this helps

-

Hi Jim,

I've used this framegrabber in the past (and similar one like PCIe-1430 and 1433).

Just to be clear, the serial communication goes through the CameraLink cables and can only be used to read/write settings on the camera.

And as far as I know the only way to use this communication is by using the VI from the NI-IMAQ sub palette "Camera Control" and these VIs come as part of Vision Acquisition Software.

It's always been working just fine for me with different cameras (Basler, Sony, JAI to name a few brands). You do have to read the camera's user manual to know how to implement the communication though.

Do you know which camera you're going to use?

-

How about using the traverseref.llb?

-

I've looked at all your posts and it looks like your asking help for your homework, if it is the case, just say it, there's nothing wrong with asking for help but you can't ask us to do it all for you.

If I'm wrong I apologize.

Anyway start writing some code and if you need help to make it work the way you want we'll help you.

-

1

1

-

-

what browser are you using?

on my mac Firefox does the same but safari downloads the video.

-

-

48 minutes ago, Benoit said:

For my part, I hate TS for the license cost and for it's advantage that is an inconvenient for me. TS is so capable to integrate anything that it becomes not user friendly. The knowledge ramp is quite hard. Doing things in parallel is not intuitive and if you want a good GUI for your operator that is multiple language... GOOD LUCK. In a manufacture context, time and clarity of instruction counts.

I create my own test framework that integrate database, debug tools, instrument command spy and overpass functionality. Everything has a "secret" backdoor to connect to the tester to see what's going on. (I

VI server) I developed a HAL "Hardware abstraction layer" level that allow the technician to change any instrument in a matter of minutes and this is 100% transparent for any test sequence that runs. Per example I support over 15 different power supply (serial, GPIB and USB). (plug it and play

VI server) I developed a HAL "Hardware abstraction layer" level that allow the technician to change any instrument in a matter of minutes and this is 100% transparent for any test sequence that runs. Per example I support over 15 different power supply (serial, GPIB and USB). (plug it and play ) I also integrated Domain login capability and so much more. Did I said that it support batch mode, single mode and asynchronous mode for unlimited test position as well as debug step by step?

) I also integrated Domain login capability and so much more. Did I said that it support batch mode, single mode and asynchronous mode for unlimited test position as well as debug step by step?

Finally, developing a test sequence with medium complexity (CAN, SPI, I2C, Ethernet, ARINC,+ instrument power supply switch, DAQ, Oscilloscope, camera (bar-code and vision inspection) and more, about 250 measurements take less than a week including deployment and validation. TS cannot offer that.

In other words, if you want all those functionality in TestStand, you need to develop them outside TestStand. Training someone on older code made in TestStand is way too long. So a huge license cost just to execute test step no thanks not for me.

By the way... I'm working for an important electronic manufacturer... High volume!!! No TestStand and happy about it.

Maybe you should give it a name and start selling it :-o

-

1

1

-

-

I think the tree control is a powerfull tool, to be able to leverage this tool you need to spend a bit of time to understand how to use it.

When I first used it I also though it was difficult, now I'd say it is a bit complex.

I encourage you to invest some time to master it!

One cool tool you can have a look to see the power of the Tree Control is Ton Plomp's variant probe available on the LAVA Code Repository

-

statement that starts at 10:00 is the key and it ends with "if it's a bug that people rely on, it's not a bug, it's a feature".

-

1

1

-

-

just thinking out loud, have you tried to use BitMan toolkit to merge the 2 images in one and then display it?

-

1

1

-

-

I've seen this, looks very promising!

I'm going to apply for a VISA

-

2

2

-

-

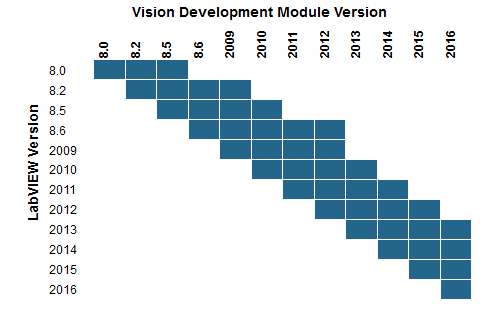

Not sure VDM 2016 is fully supported with LV2017, check this : http://digital.ni.com/public.nsf/allkb/244E6DDF9A92A6CD8625730100629047

if you extend this

-

On 10/14/2017 at 7:07 PM, ShaunR said:

anyone who upgrades before SP1 is out is also insane

people do that??

-

AQ, this VI seems to be password protected, at least in LV 2014 and 2016.

-

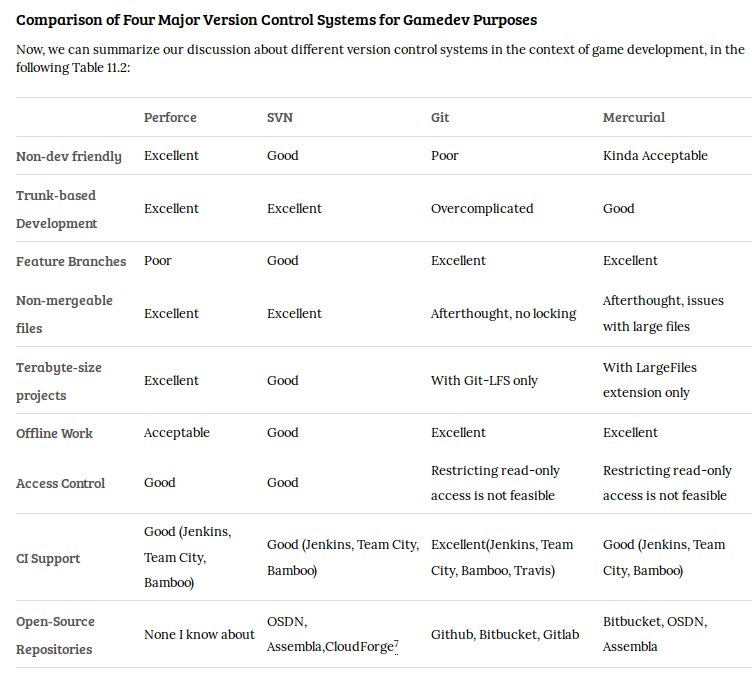

I saw this recently, maybe it can help you make a choice :

source :

-

1

1

-

-

Want performance? Go the NI way, use one IC-3173 per camera.

-

23 hours ago, Neil Pate said:

If I had a cent for every time I have created and deleted the register event terminal which never propagates properly...

same here

-

Well... you're not giving much information about your application.

What kind of camera are you using? USB? FireWire? GigE? Camera-Link? CoaXpress?

From the users' point of view, would it be more practical to have all the camera on 1 computer?

[CR] UI Tools addon: Control class

in Code Repository (Certified)

Posted

Ha, I think I found the issue, I should have let VIPM mass compile the package after installing it.

I had to move "Create control.vi" out of the C:\Program Files (x86)\National Instruments\LabVIEW 2018\project\UI Tools\Control Generator, open it, mass compile it place it back and now it all works fine.