-

Posts

132 -

Joined

-

Last visited

Content Type

Profiles

Forums

Downloads

Gallery

Everything posted by Ano Ano

-

Hello, I got this side project and I need some help calculating the quotation that I should give to the customer as this is the first time I am doing this. Lets say that the hardware cost is "X" and the time that I spend writing the software is "Y". I charge "Z/hour" and spend "W" on gas, calls etc. Hence the total cost for the client is: X+Y*Z+W ? Or should I add a profit margin on top? Is there anything else that I should consider adding to the quote? Thank you in advance

-

Thank you both for your fast response. So basically the cRIO is not as easy to use while troubleshooting code... Does it take long to recompile/download the code to the cRIO's FPGA? The cRIO-9064 that I am thinking of using, is a linux system. Can I use a host windows based PC to write the code and download it to the cRIO? Will it work?

-

Hello, Usually when I want to acquire data I use a cDAQ chassis connected to a PC. I am thinking now for a new project of using either a CompactDAQ controller or a cRIO like the cRIO-9064 to combine both PC & module chassis. Since I have never used the cRIO or FPGA systems before, my question is: During the process of writing code & trials, can I connect it on a PC, like I used to do with the cDAQ, or do I need to build/embed code on each software change? Thank you in advance,

-

Hello & thank you for the fast responce. I just noticed I forgot to attach the vane meter manual, so I am including it in this post. The manual mentions a 5V or 12V pulse. Should I use a cDAQ like the NI 9361 for counting the pulses or an analogue input module like the NI 9205? proflow_manual_en.pdf

- 3 replies

-

- vane meter

- pulse

-

(and 1 more)

Tagged with:

-

Hello, In my new job they requested me to acquire date from a vane meter (flow meter) that gives pulses/litre that flows through. The vane meter is the https://www.vaf.nl/media/1078/proflowmeters-b5xxx-with-n-counter-sn-plus700000-english-tib-141-gb-1113.pdf?type=Manual%C2'> Pages 11-13 I am more used to analogue signals rather than digital/pulse. This is the first time I have to translate pulses, their width etc to liquid quantity so I am confused on how to do it. I need some assistance on what NI hardware to use, how to connect it and the software methodology to use. Thank you in advance

- 3 replies

-

- vane meter

- pulse

-

(and 1 more)

Tagged with:

-

Hello, I recently upgraded my PC from Windows 7 32bit to 64bit. Since that day every time I restart the PC I have to start the ni configuration manager. On top of that I also get a drawmgr.cpp line 2931 error and sometime NI MAX shows a "There was a problem resetting the device. Error code: 80040383". My configuration is: LV 2010.01 NI-488.2 3.1.2 MAX 5.5 DAQmx 9.8.0f3 VISA 5.4 Serial 3.9 How can I solve these issues? Thank you in advance

-

Hello, Avast mistook nipalu.dll as a malicius file and deleted it! Is there anyone out there running Labview version 10 to send (upload in this post) this file? Otherwise I have to reinstall Labview! Thank you in advance!

-

Hello, I am trying to make changes in the mathscript codes in an old & rather large vi with many subvi's. These mathscript codes are many & everywere and I am wondering if there is a way to "probe" the main vi & find where they are (or how many are there) so that I will not miss a few in the process. Thank you in advance,

-

Hello Todd, Yes, it is expected, but when you have 10 controllers and 1 is switched off (closed or damadged), the code stops due to the timeone on this controller! I would prefere if the code searched for a controller and if not found, return with a zero, instead of closing.

-

Hello, I bought a 3216 controller, and I can communicate with the instrument just fine via the Labview drivers. I am trying now to set the code in order to communicate with 10 controllers in series. I made a 10-iteration For Loop and in each loop it sends the iteration number to the controller as a unit id (by the way this works on Omron controllers). The aim is to get at the end of the For Loop and array with temperature values from all the controllers. When it tries to read from the other controllers (which dont exist because I only have one) I get an error: Warning 1073676294 occurred at VISA Read in Eurotherm 32xx Series.lvlib:Utility MODBUS RTU Receive Message.vi->Eurotherm 32xx Series.lvlib:Utility Read From Register - Floating Point.vi->Eurotherm 32xx Series.lvlib:Utility Read From Register - Float or Int.vi->Eurotherm 32xx Series.lvlib:Read Process Variables.vi->Eurotherm 3216 Read & Write v1.2.vi->Eurotherm 3216 Control & Monitoring v1.5.vi Possible reason(s): VISA: (Hex 0xBFFF0015) Timeout expired before operation completed. I tried increasing the instrument timeout time but it did not solve the issue. I am sensing that this may not be the optimum way to controll "Nth" controllers. Does anyone have a suggestion? Thank you in advance!

-

Yes that did the trick! Thank you very much

-

Hello, I want to connect via the RS232 two pc to send data (string) from one to the other. I tried the "Basic serial Write & Read.vi" but I cannot seem to be able to communicate. Any ideas on why this is happening?

-

Hello, I need to design a feature in my application where the client/remote user can register the software via the internet. Hence, It will need to send a string my company server and from there another application to read and store the string. Any ideas on how to do it?

-

Thank you for your prompt reply. The management wants to ensure that no one will/can replicate the system regardless where we sell it. So its not a particular dodgy client. In essence what I as the developer want to do is find a security method so that the software works with specific devices (or choose from a list, incase one fails) and there is some sort of license key. This license key needs to be in the same methodology as with the windows keys ie I burn "X" amount of cd/dvd with the same software and have a set of keys that will activate the program.

-

Hello, I am building an application that interrogates up to 4 NI-9191 wirelessly. I want the application to identify and use/connect only the NI-9191 that I will supply to the client. The reason for this is to void cheeky clients that might be tempted to "replicate" the system. Is there any way that I can write a specific number/id to the NI-9191 so that when the application is launched, to read all wireless NI-9191 out there and connect only to the devices with this specific number?

-

Thank you all for the suggestions. Ton : The .exe crashed on my developer & on another developer system with the same LV version (10.1f4 & DAQmx 9.6) Mellroth: Yes, I did refreshed MAX and I kept having this issue. asbo: I ended up uninstalled all Labview component and installed only the LV 10.1 that came with the DVD. This did not work either so I backed up everything....and formated the drive! After re-installing LV 10.1 (DVD only) I was able to build everything properly:)) I will try to upgrade to DAQ 9.5.5 which was the last stable version for me and wait for a 9.6.5 or something similar...

-

-

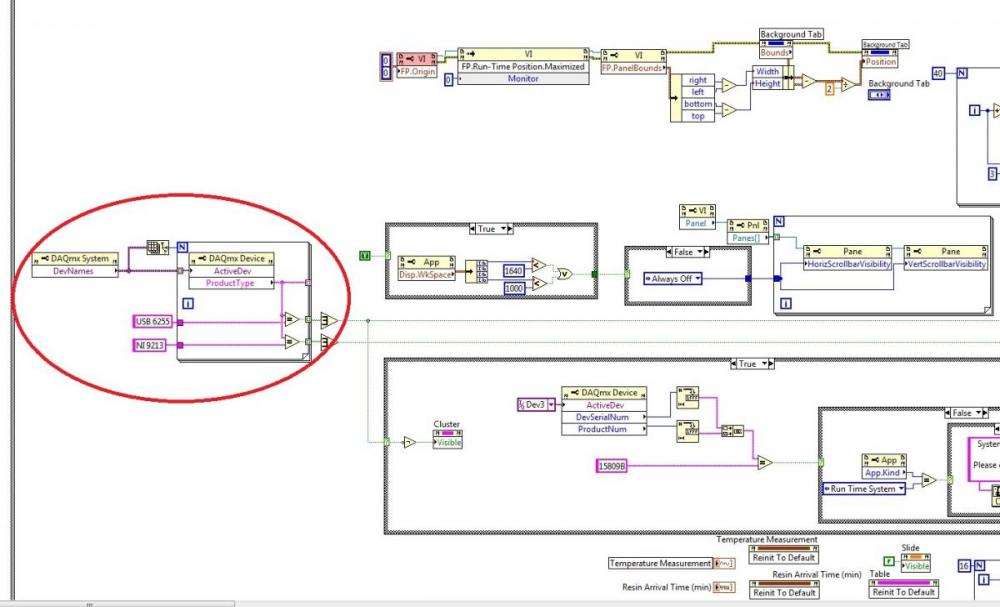

Hello, At the start of my vi I have a DAQmx System property node to detect the NI products that are connected on the pc. when I run the vi everything works perfect. When I built the application the .exe freezes when it reaches the DAQmx System propert node. I even tried to make a vi with only this property node in it and built it to an .exe, and as expected it froze! I am running Labview 10.01f4 and this issue appeared after installing the latest LV update & NI-DAQmx 9.6. Has anyone encountered this problem? Any ideas how to solve it (without uninstalling everything:P) Thank you in advance

-

This file is written with Labview v11, can you please down-convert it to v10.1?

-

Thank you for the help I just started another thread on this topic:

-

Hello, I have a Omron E5CN Temperature controller that I want to use with Labview and Modbus. I am able to communicate with this controller using Omron's Thermomini software. MAX is able to validate the and open a session with the device. The controller is connected via a RS232 to USB converter. I set the controller to modbus but no luck. Maybe its because I dont know how to use the modbus drivers, I havent attempted to use such a device with Labview so I am lost with all this machine codes ! Any advice towards a newbie on how to use this controller with Labview/Modbus? The programming manual for this controller is here

-

Yes I did set it to modbus, maybe I dont know how to use the modbus drivers, I havent attempted to use such a device with Labview so I am lost with all this machine codes ! MAX is able to validate and open a VISA session but this is as far as I can get with it.

-

Unfortunately I do not have the DCS/OPC. I downloaded the Modbus drivers from the NI site but I was still not able to communicate with the controller. You mentioned something about linked VI's...

-

Hello, I tried the Hyper Terminal code that you wrote but I was not able to communicate with my device. I have a Omron E5CN Temperature controller that I want to use with Labview. I am able to communicate with this controller using Omron's Thermomini software. MAX is able to validate the and open a session with the device. The controller is connected via a RS232 to USB converter. Any advice on how to use this controller with Labview?

-

Hello, I am looking for a temperature controller to control with Labview. I want to use Labview to input a custom temperature profile to the controller. So far I tried to use the Omron E5CN but I cannot find a way to communicate with VISA/Compoway/Modbus & RS485/232 ports. Does anyone know an alternative controller that is straightforward to use with Labview?