Search the Community

Showing results for tags 'labview'.

-

Hello, I'm not sure if this is the right forum for a question like this. I'm pretty new to LabVIEW and have a background in mathematics and computer science. I have a lot of interest in LabVIEW and want to become better at it. I have been trying to figure out what fields of maths would be beneficial to study that would help with LabVIEW programming. I was thinking graph theory since a lot of the LabVIEW interface is making graphs, so having an understanding of graph theory may help with efficiently making large programs or with algorithms. I'm curious if any of you have studied certain fields of maths and found them to be applicable to your LabVIEW programming.

-

Does any one have an idea on how to password encrypt an Excel file (or csv) in LabVIEW or zip up the excel file/csv and add a password to it that way? I need to be able to add a simple encryption to confidential patient data files after they are created and be able open them to read later by the same program. I've tried using OpenG to add a password protection to a Zip file but when I try to add a string variable to the password connector it says password (none) so it makes me feel like I'm doing this wrong. I couldn't really find any similar documentation or tutorials on creating a csv or excel file then zipping up the file and adding a password to the zip with OpenG though I read about the function on the Labview forums. A few other things over I've tried recently: I think a solution would be to use some sort of property/ invoke node with ActiveX like I've attempted to do in the picture below but I can't find anything that explains exactly how property and invoke nodes work with ActiveX to achieve what I wanted, and I was hoping someone would have a tutorial that a LabVIEW beginner like me could use. Something else that I looked at was adding a "blowfish" encryption to encrypt the data but seemed extremely complicated and all I need is a simple password encryption. Finally I tried using an add on called AES crypto but I felt that the encryption methods that were featured in the add on were limiting. For patient names they would be at different lengths and in the example programs it showed that if a string was shorter than 128 bits then it would't be able to encrypt the string. Which is an issue if the patient has even a regular length name. If you have any thoughts or find anything useful let me know. Thanks, From a beginner usmanf

- 2 replies

-

- labview

- encryption

-

(and 2 more)

Tagged with:

-

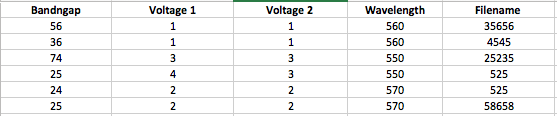

Hello Labview Users, I happen to have thousands of csv data file that I work with. The only way I recognize them is putting their characteristics in the file name. Which brings the problem of making the names too long and Microsoft doesn't like to accept long name. So I wanted to build a database for all my files. I am in the preliminary stage of building it ( I have attached the file and some of you may have seen it before). What I want to do is, have all my files in the database with random names and list them based on their characteristics. I want to do that in my application in the place of 'file' box. So that I can click on the file and run it (double-click on the file in application to make them work in active file). based on the parameters listed on the database I want to filter them to find any specific file. How the interface of database should look like is shown blow (Image) . It doesn't have to be a real database, just a directory application. I am trying to make it without the database toolkit. If anyone can help me out and guide me out or guide me in the right direction then that would be great. Thanks. Multicolumn list box v1.5.vi

-

Hello, Is it possble to put signatureline into excel footer using Active X ?

-

Hello everyone, I am planning to give CLD exam but my question is: is this certification make any significase difference ? If yes, then where can I find proper guidance for preparation of this exam. Thanks.

- 9 replies

-

- labview

- certification

-

(and 1 more)

Tagged with:

-

Bonjour, Je recherche pour une mission longue durée (1 an minimum) en région parisienne un(e) ingénieur(e) LabVIEW & TestStand expérimenté(e). Une certification CLD/CLA et/ou CTD serait fortement appréciée. Un backgroud en électronique/mécatronique serait un plus. Disponibilité ASAP Français obligatoire. Contactez-moi en MP ou par Mail

-

Hi, I am french LabVIEW consultant available for worldwide remote work up to 10 hours per week. Please find attached my resumé. Don't hesitate to contact me for further informations. Regards, Jean LINISA https://www.linkedin.com/in/jeanlinisa/ DC_Jean_Linisa_English.pdf

-

NI Week is just around the corner so I was wondering when the LabVIEW 2017 installers would be published...and found out they are already out Here are two of the downloaders: ftp://anonymous@ftp.ni.com/evaluation/labview/ekit/other/downloader/2017LV-WinEng_downloader.exe ftp://anonymous@ftp.ni.com/evaluation/labview/ekit/other/downloader/2017RealTime-Eng_downloader.exe

-

At BD Becton Dickinson & Co., you’re one person making one big difference. You’re a key member of a team that is an important part of a leading, purposeful company committed to advancing the world of health. No matter what role you play, you can be confident that you’re improving lives, all over the world. And as you progress with us, your impact will only grow. Responsibilities -Design and develop PCBA and subsystem test fixtures -Investigation and provide failure analysis for PCBA and subsystem unit failures -Lead development of automated test solutions for PCBA, subsystem and system level tests -Maintaining and servicing existing automated test fixtures -Work with cross functional teams -Effectively managing and supporting contract manufacture Requirements -Fluent in LabVIEW -Minimum degree of BSEE or equivalent -7-10 years experience in test development -Experience in EE and strong capability in PCBA troubleshooting and failure analysis -Strong problem solving skills Please contact: Email: Kenneth_Partyka@bd.com Phone: 603-583-1456 LinkedIn: www.linkedin.com/in/kennethpartyka Website: www.bd.com/careers https://jobs.bd.com/job/san-jose/staff-test-eningeer/159/4254802

-

- job posting

- labview

-

(and 1 more)

Tagged with:

-

Hi, I am Certified LabVIEW Developer and looking for LabVIEW based work/project. Feel free to contact me for your requirement.For me customer appreciation is first and money is secondary

-

- prevailsofttronics

- entrepreneur

-

(and 3 more)

Tagged with:

-

Hi! I am looking for a Senior Software Developer to work on our LabVIEW based sensors and applications. I am also looking for Senior Software Developer(s) available for contracts (somewhat local to London) . Please note that this is about product development in LabVIEW (as opposed to test development). More info here: https://silixa.com/about-us/careers/

-

- developement

- application

-

(and 2 more)

Tagged with:

-

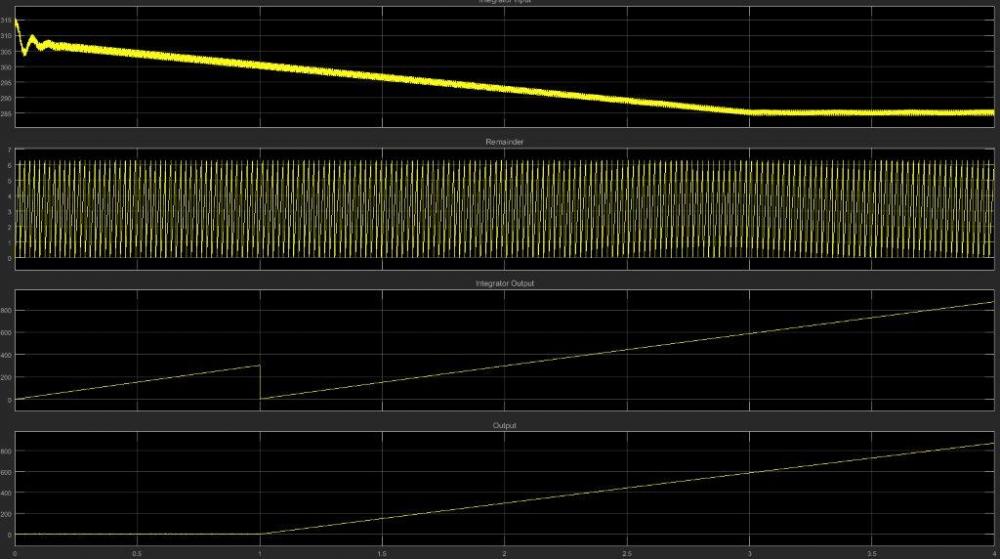

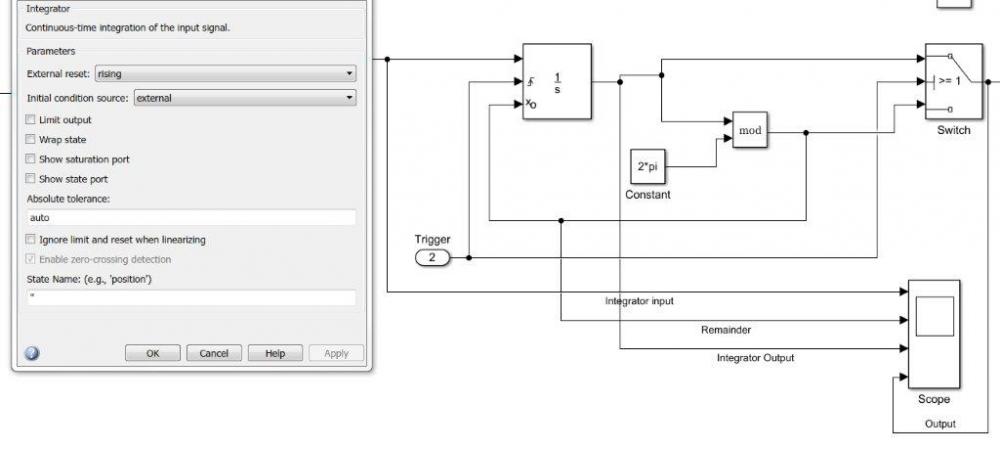

Hello, everyone. Recently I came across one issue, that I solved within a couple of minutes in Simulink, but cannot crack for a couple of days in LabVIEW. It is a Rising integrator (model and plots from Simulink attached). Mod is the modulus function (i.e. remainder), the integrator reset is triggered by the external “Trigger” signal at 1 sec. After that, as you see the integrator generates a ramp signal. I was trying to represent the same behavior in FPGA LabVIEW in order to use it further on my cRIO. I’ve seen on the forum, that one of the most feasible solutions for the Quotient & Remainder function (i.e., Modulus in Simulink) is the use of a while loop system with subtraction. But the behavior of the system is different since it generates a ramp signal after the reset is on, but it has a negative slope and saturates at -37k. Just to check in general how the approach works in LabVIEW, I’ve designed the second model with a Quotient & Remainder block (I know that for FPGA it is not the best option, plus I could not figure but how to use it with FXP values). But this model generates the output with a value of 5. Which is even more questionable. In this case, could you please advise what I am doing wrong with the FPGA code for the block? Since FPGA is the main reason, why I am looking for any options but not to use the Quotient & Remainder block. Thank you in advance. P.S. The models are designed in LabVIEW 2014 SP1. Integrator_SGL.vi Integrator_while_loop.vi

-

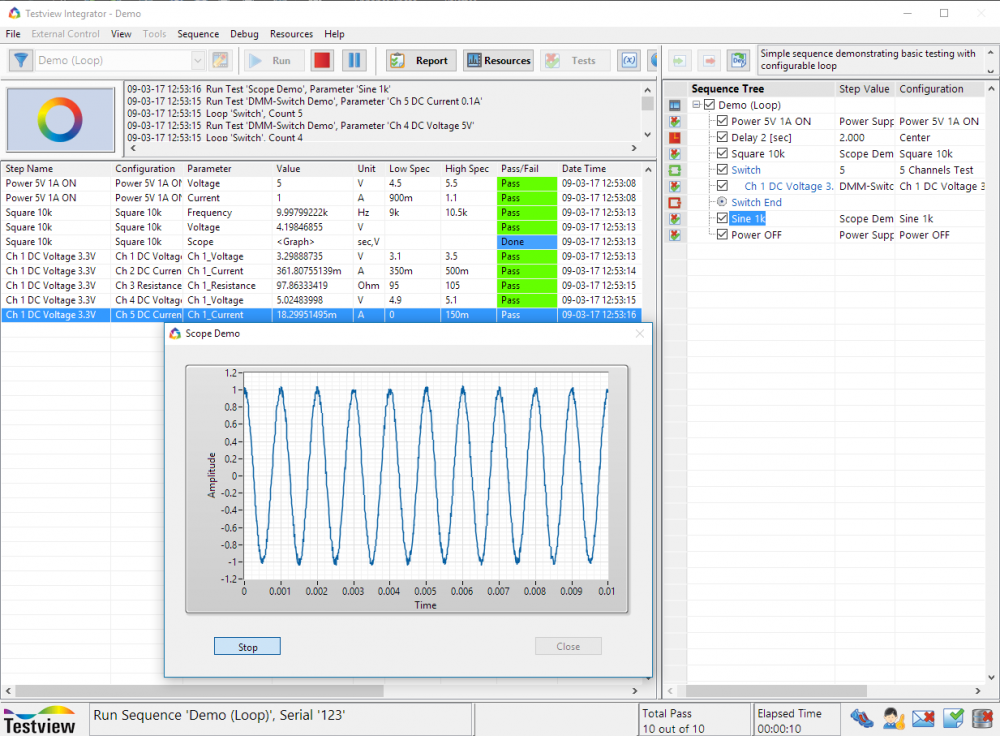

Hi all, We're excited to announce the public release of TVI – our industry-proven test management framework for LabVIEW: http://tvi.co TVI is a flexible and easy to use test sequencer and reports generator for LabVIEW based functional testers. Key features: Simple and easy to use user interface Very short learning curve Creating test sequences in few clicks Viewing results in real time Exporting of data in various formats (CSV, PDF, HTML) Seamless integration with LabVIEW enables to write/edit tests directly from TVI (developer mode) Editing sequences and test parameters on the assembly line stations (runner mode, no need for LabVIEW) (TVI does not require TestStand to run) See it in action here: https://youtu.be/7Job4qMc66w We’d love to get any feedback! Thanks, Avital

-

LabVIEW Software Developer SIGMADESIGN is a fun, fast-paced engineering consulting company currently experiencing explosive growth. We are looking for a LabVIEW Software Developer. Curiosity, competency and confidence are a must. We offer competitive compensation (DOE), Medical, Dental, and Short Term Disability insurance, a retirement plan, and profit sharing. We also offer Voluntary Benefits: Vision, Long Term Disability, and Term Life insurance. Primary Function: Definition and programming of LabVIEW based software. Duties include: designing, developing, installation, and debug of custom LabVIEW based applications for a variety of monitoring, measurement, and control systems. Systems will incorporate a variety of technologies (DAQ, machine vision, motion, FPGA & real-time control, etc.) with application across a broad range of industries. Essential Job Functions - Responsibilities: · Develop and maintain LabVIEW applications for control and data acquisition across a wide range of test and measurement systems. · Interpret and understand control specification documents, P&ID drawings, wiring diagrams, and schematics. · Utilize National Instruments data acquisition hardware, off-the-shelf test equipment, and custom developed hardware. · Troubleshoot software and electrical control issues and define and/or implement solutions. · Support, improve and modify existing LabVIEW applications as necessary. · Create and maintain documentation, version control history, and bug tracking for LabVIEW applications in coordination with engineering and technician teams. Required Education, Skills, and Experience: (Knowledge, skills, & abilities) · CLD (Certified LabVIEW Developer) certification or above is required. · 5+ years LabVIEW application development experience with demonstrated proficiency. · Experience with NI DAQmx, NI VISA drivers, and supported protocols (GPIB, RS232/RS485, TCP/IP). · Experience with at least one version control system and an issue tracking system. · Attention to detail in design, programming, debug, and documentation work. · Ability to organize and prioritize numerous tasks and complete them under time constraints. · Ability to plan work and accomplish objectives with minimum of direction. · Strong written and verbal English language communication skills. Additional Desirable Skills, Education, and Experience: · CLA (Certified LabVIEW Architect) certification highly desirable. · Bachelor’s degree in Engineering or a related field highly desirable. · LabVIEW Real-time and FPGA Programming experience. · LabVIEW Object-Oriented Programming experience. · Experience with developing Motion and Vision applications. · Experience with CAN and Modbus network protocols. · Familiar with basic relational database concepts. · Linux OS administration and shell scripting experience. · Experience with Matlab and Simulink. · Additional software skills (C/C++, PHP, Python, etc.). · LabVIEW for calling external code (dll, COM objects, ActiveX, .NET, etc.) · Translation of source code from various languages (VB, C, C++, C#, Python) into LabVIEW code. · Calling VIs dynamically. · Experience with LabVIEW version 2012 or newer. · Pass a post-offer background check verification. · Complete Pre-Employment Assessment required: Begin Assessment In addition to submitting your application, please complete the Pre-Employment Assessment to be considered for this position. Work Environment: Standard office environment with normal amounts of office related conditions. Occasionally may be required to work in environmental conditions that emulate typical user environments in order to facilitate design testing and validation. Sigma Design - Corporate Fact Sheet.pdf

-

- labview

- employment

-

(and 3 more)

Tagged with:

-

Hello to all. First of all thanks a lot for reading this post. I have a while with event structure. The event structure has the next two events: · Timeout: each 25ms, this timeout reads variables from PLC. · Button event: When user press this button, a dialog box appears to ask "yes or no" to user. Well, here maybe there is a problem because if usser takes more than 25ms to enter an input in dialog box then timeout does not run in that iteration and It is critical for me. Is there any way to do that program runs and it does not stop until usser put an input in dialog box? Or the best way is to do another event structure in another while with button event? Thanks a lot.

- 14 replies

-

- dialog box

- labview

-

(and 1 more)

Tagged with:

-

Hi, Zernike polynomials are extensively used in Vision science, adaptive optics and optical metrology to represent different type of wavefront aberrations. I am currently working on a labVIEw project that require the Zernike surface fitting to the experimental data. I can write the code myself but it will take little longer. want to know if anyone in this group has used the Zernike polynomials and willing to share the LV code? plz feel free to respond. Cheer Jimm

-

- labview

- zernike polynomials

-

(and 2 more)

Tagged with:

-

Hello, I am trying to use classical touchscreen moves on my LabVIEW application. The problem is I really don't know how read the information coming from Windows indicating the type of move (zoom rotate, span,...)! I tried to use the Windows message queue library (using user32.dll) with the message WM_TOUCH and WM_GESTURE but nothing works. I don't know if it's compatible... Does anyone tried to do this? Thanks for your help!

- 2 replies

-

- touchsreen

- labview

-

(and 3 more)

Tagged with:

-

Hello to all. I have an image and a ROI. I would like to get the minimun distance between the first edge and the last edge in horizontal position. See image attached. If every edges found are in color yellow I would like to get the distance between edges in red (minimun distance from last edge to last edge in horizontal direction. I have tried to use "IMAQ Clamp Horizontal Min VI" but this VI does't the option "from first to last edge" and the only way to get what I want is to play with contrast but it is not work for some of my images. So is there any way to get what I want? Here is the image. From fist edge to last edge I mean from left to righ, the first edge found and last edge found. Thanks a lot.

-

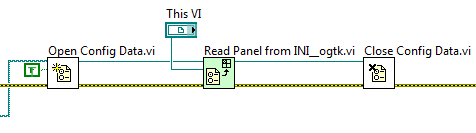

Hello to all. I have an application wich use; imaqdx (displays...), sliders, many controls and many indicators, and everything in a tab control of 3 pages and 2 subVI. I am trying to use "write and read panel to/from ini . vi". The first thing that my program does is to read panel from ini. Here there is the first problem because it gives the next error: "Error 91 "The data type of the variant is not compatible with the data type wired to the type input. Set control value" Here is my piece of code in image attached (boolean input in open.vi is True). I notticed that it gives me an error if the .ini file does not exist (but it should work even .ini file does not exist). Well, my next step was to create a .ini file before to use "read panel from INI.vi". So I use "write panel from INI.vi" and it works fine. It does not give me any error. and the ini file is the next: [medir.vi] Boca = "0,000000" Camara 1 Configuracion = "\00\00\00\1Dremote image 0000000013F9C704\00\00\00\0Anivissvc.*\00\00\00\13LV_ImageDTClassInfo\00\00\00\01\00\13)É\00\00\10\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\10\00¬\00\00\00\00\00\00\00\1D)\13\00\00\00\00\00\00\00\00\00<\04\00\00\00\00\00\00<\04\00\00\00\00\00\00\03\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00€\04\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00DÊù\13\00\00\00\00LÌj\0F<\1E\00\00ø\08\00\00\00\00\00\00\00\00\00\00\01\00\00\00\01\00\00\00\00\00\00\00\1D\00\00\00\00)\13\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00remote image 0000000013F9C704\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\0ÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿúïêôÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿËž“Š„€z€}{zzwx|{wwxswyvttquvrtqpprqsrpvppsquqqusputquxusswwssttvwtwt}yqvuxuzvvuwtwvvtvrwrqpupgc\\XYZX\\XW[[UVVWUXTRTRURUQQSPNQNNOKKLKLJLJFEDEEBBC?B??=:>@CDHGHHIJGJEGDFEHJGFDBADDCCEDBCFILS^ao€–³Òñÿÿÿÿÿÿÿÿÿÿÿÿ\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00ÿÿÿÿÿÿÿÿÿÿÿÿÿÿìÛËÚ̾¶³³³¼³Àìÿãϸ¬ª£¤œ‘‘‹Ž‰Œ‡…€†~z~}x{||}z~xx}}v{syx{vwwwzyywxxxxwwuruwzyvwszvzt{z{yv{wy|{vyw{zzwy~y}xzz}y{|€†€‚€€‚ƒƒ†}‡ƒ…‡‡†‹ŠŒŒŽ‹‹•š’–”›žœ› ¡¢©©©±²µ¶º½ËÒåÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿýëä÷ÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿ Ž‹…†|ƒ}~xv~z{zu{wvvvuutvssqssusotqrwruxtrpqrrotusrvuwywrsuusyxvywxtvsvwuuwvwywquvvuvswtvqpplge^\\VYWYXWYXSWVUZUVQSUTSRTTUNONMKMMKKMJLLLJGEDC@CA?@@@??=CBDGGJLJIJGGIGHEFGFHHCBCBADCAADDIOWZiq„œ·Ôïÿÿÿÿÿÿÿÿÿÿÿÿ\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00ÿÿÿÿÿÿÿÿÿÿÿÿÿÿåÙ×âɺµ®¶¶³·ÍýÿßDz¨¤¢¥š–“‰ˆ‰…‚‚‚~~z}x}}~xxxwyy}xwzwzvywuvxyuxtvyxvvwtyqvpzv|zvzzy{xzzzxx{yxyzyzxw}{y~{}|~€{{|‚‚„ƒ‚…‡€{‚‚„‚‡Š‰‡‰Š‹ŠŒ‰ŒŽ‘Ž’••’“š™žš™›Ÿ¡§ž£ªª®²´»½ÂÉÚïÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿøàéÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿÿô»žŒˆƒ€~}~}||w{yzxuwwuxvrtvtvtrqpuotqppttvtxsstqqtrtpswtwwvsusuvwxxxxvxuxxvvtx{ux{uuvttxtsssspoja\\Z\\YYZXWYWSSWXWWUSRPTUQSRNQPQNOLNLLKJJIHFFHECA?A?><@?=?ADHFELIHHJIIGEHFGJJDEFBCBECEACDGJPX_fs‡¢»Úóÿÿÿÿÿÿÿÿÿÿÿÿ\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00\00ÿÿÿÿÿÿÿÿÿÿÿÿÿÿé×Ýã¾·®´´Âº»Ò Camara 2 = "0,000000" led_boca = "FALSE" Buena_boca = "0,000000" mala_boca = "0,000000" Espiga = "0,000000" led_espiga = "FALSE" buena_espiga = "0,000000" Bulbo = "0,000000" led_bulbo = "FALSE" buena_bulbo = "0,000000" Cuello = "0,000000" led_cuello = "FALSE" buena_cuello = "0,000000" mala_cuello = "0,000000" Cuerpo = "0,000000" led_cuerpo = "FALSE" buena_cuerpo = "0,000000" mala_cuerpo = "0,000000" Excentricidad = "0,000000" Buenas = "0,000000" Malas = "0,000000" led_excen = "FALSE" EXCENT = "0,000000" Camara 2 Configuracion = "\00\00\00\15Threshold Destination\00\00\00\0Anivissvc.*\00\00\00\13LV_ImageDTClassInfo\00\00\00\01\00\00\00Á\00\00\10\0000\00\00\03\00\00\00\00\00\00\00\\00\00\00\00\00\00\00Threshold Destination" Excentricidad.<size(s)> = "6" Excentricidad 0. = "<size(s)=0> " Excentricidad 1. = "<size(s)=0> " Excentricidad 2. = "<size(s)=30> 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000" Excentricidad 3. = "<size(s)=30> 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000" Excentricidad 4. = "<size(s)=30> 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000" Excentricidad 5. = "<size(s)=30> 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000 0,000000" Nivel de luminosidad = "157,666672" led_luminosidad = "TRUE" Distancia promedio = "46,131313" Bordes encontrados = "33" Camara2_grafica = "0,000000" Dist_Cuerpo_Cnfig = "0,000000" Dist_Boca_Cnfig = "0,000000" Dist_Espiga_Cnfig = "0,000000" Dist_Bulbo_Cnfig = "0,000000" Largo total = "0,000000" led_largoTotal = "FALSE" cuello_config_cluster.Left = "0" cuello_config_cluster.Top = "0" cuello_config_cluster.Right = "0" cuello_config_cluster.Bottom = "0" cuello_config_cluster.Rotation = "0,000000" top_cuello_prod = "0" botton_cuello_prod = "0" PLC_Valor_Cuello = "0" ampolla_ok_prod = "FALSE" num_disparo_cam1 = "0,000000" PLC_Valor_Espiga = "0" PLC_Valor_Cam2 = "0" lim_min_ambar_boca = "0,000000" lim_max_ambar_boca = "0,000000" Largo Total.<size(s)> = "1" Largo Total 0. = "<size(s)=0> " Tab Control = "Camara 2" Cluster.Numeric = "0,000000" Cluster.Numeric 2 = "0,000000" Cluster.Numeric 3 = "0,000000" Cluster.Numeric 4 = "0,000000" Cluster.Numeric 5 = "0,000000" I resume "camara 1 configuration" because the rare symbols are about x10 more. Well, next step is to read this .ini file and now it does not give me any error but it stacks in "read panel from ini.vi" (maybe it takes about minutes for reading .ini). How can I do to write and read panel to/from ini well? It is very important for my application. Maybe there is another library that I can use? Thanks a lot!

- 10 replies

-

Hi to all. I would like to create an application where usar can train an OCR programmatically. So do the same that vission assistant when user trains OCR but in an application. So, take picture from a camera (I have already done this) then click button, select area to train and put the train (for example type "9" if the image is a number 9). And save it. And if for any reason PC is shutting down, application can remember the train. That is possible?' Thanks a lot!

-

Hello to all. I think this is an interesting topic and it isn't easy to find out on the internet. I would like to know (more or less) what is the price that a company pay to another for an applications developed in labview. I am new in that and I have to develop a product and I don't know which price I should ask for. Apart of hours worked, gas etc etc I would like to know the market price more or less of these applications. My application I have to develop is an artificial vision application which will use "Vision Adquisition Software" and "Module Vision Toolkit". I am asking for (more or lees) about the market price of the software (not the hardware). Thanks a lot.

- 1 reply

-

- labview

- applications

-

(and 1 more)

Tagged with:

-

Hello to all. First I explain my environment and then I will ask the question. PC 1 (development PC): intel i5, windows10 64bits, 8GB Ram, Labview 2015 SP1 (32 bits), Vision Adquisition Software 2015, Module Vision 2015, DSC 2015, ni OPC Server. PC 2 (deployment PC) : intel celeron 1.99 GHz, windows 7 64bits 8GB Ram, Labview 2015 SP1 (32 bits), VIsion Adquisition Software 2015, Module Vision 2015, DSC 2015, ni OPC Server, Run Time Engine 2015, VIsion Run Time 2015. PC 3 (deployment PC) intel Atom CPU N2600 1.40GHz, windows 7 64bits, 4GB Ram, Labview 2015 SP1 (32 bits), VIsion Adquisition Software 2015, Module VIsion 2015, DSC 2015, ni OPC Server, Run Time Engine 2015, VIsion Run Time 2015. I use the next in my aplication: 2 cameras GigE Lan connected to PC. A PLC connected RS232 through ni OPC server and about 15 shared variables. In development environment my application works well. In PC 2 a executable of my application works well. But the problem is that the same executable works bad in PC 3. Front Panel is slow and displays of image cameras don't refresh the image well. So all my application is slow in PC 3. What can it be? I don't think that it could be the specification of PC 3 but I don't know... Does anyone fix something similar? Any help will be appreciate it. Thanks a lot.

- 14 replies

-

- executable

- labview

-

(and 3 more)

Tagged with:

-

View File Threshold Hysteresis v1.0 LV8.6.1 The Threshold Hysteresis VI allows an input (for example, a sensor) to drift out of an inner limit without generating an invalid flag, but if it drifts outside an outer limit it then becomes invalid. For the reverse, when the input crosses back into the outer limit it remains invalid until the value falls inside the inner limit. For simplicity, only one input parameter is provided for both the inner & outer limits, and is negated for the lower limit, as generally tolerance limits are equidistant from the nominal. Submitter Deon Submitted 11/10/2014 Category General LabVIEW Version License Type

- 1 reply

-

- hysteresis

- threshold

-

(and 2 more)

Tagged with:

-

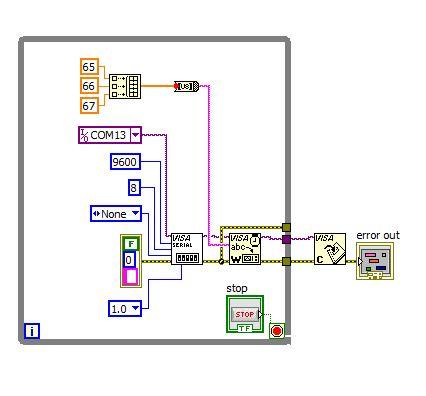

Hello, I need a little help. I want to send from LabVIEW to Arduino via serial port the string for example "ABC" and so on. The problem is that when I send the string from LabVIEW .......the Arduino do nothing. Sometimes shows some kind of sign. When I send the string via Visual Studio it works perfectly. Is there someone who can help me. I attached picture of vi and Arduino code Thank you very much. Arduino code.txt

- 6 replies

-

- 1

-

-

- serial port

- labview

-

(and 2 more)

Tagged with: