Search the Community

Showing results for tags 'labview'.

-

Hey all, I am trying to create a fairly large program. What I want to do is for someone to upload a text file, customized so I can create statements for it, and then labVIEW will read the the text file and perform actions. Specifically, the text will contain pin numbers, on/off status, wait delay, and another on/off status. The pin numbers correspond to a Boolean indicator array. The on/off status tell the Boolean indicator array to turn on/off. The wait delay tells the program to wait how long before changing the indicator array value again, and the second on/off status turns the Boolean array on/off after the wait delay. I cannot get the part where I want the Boolean array to change status after the wait delay. I am thinking the method of doing this would be a local variable, or a property value node. But, when I tried it, it would not even let the original status to turn on/off the indicator Boolean array, let alone changing the status after the wait delay. I have attached my code and text file (tab delimited) for another method of explanation. Altenbach wrote a big portion of the code for educational purposes If you delete the local variable, you will notice that the boolean array changes based on the first text column, versus it being constantly Gray if you have the local variable. ExcelTest.txt Text Boolean.vi

-

When Launching LabVIEW (14.0.1) on Windows, I get the splash screen and "Converting Toolkits..." for almost 5 minutes every time I start LabVIEW. Im sure this was not always the case (and I would have imagined that a toolkit conversion would only have to happen once, not every time I launch the development environment). Does anyone know why this is happening and/or how to improve this issue? Many Thanks, Alec

-

Please contact Dave Bowers at David.Bowers@spacex.com for further inquiries. Engineer The Future SpaceX is a U.S.-based advanced technology company founded by residing CEO and CTO, Elon Musk. Founded in 2002, SpaceX builds rockets and spacecraft from the ground up, including cutting edge electronics, software, vehicle structures, and engine systems. The Falcon Launch Vehicle and Dragon Spacecraft programs are some of the most ambitious engineering systems in the world, designed to support our ultimate goals of aviation-like spaceflight capability and making humanity a multi-planet species. Our team is made up of more than 3,000 SpaceXers located across our Hawthorne, California headquarters; and other facilities in Florida, Texas, and Washington, DC. Advance the course of human history and pave the ways to Mars This is SpaceX. We are not like most companies. Our goal is to do what has never before been done--enabling mankind to live on other planets. We push the boundaries of what is currently possible, and understand it takes rare individuals to help us make this happen. We celebrate our successes, and each other. We seek future colleagues with a rare mix of drive, passion, scrappiness, intelligence, and curiosity to seek what’s beyond the stars. Playing a direct role in advancing the course of human history is no small endeavor. Join us, and find your place in the SpaceX legacy. The Department Avionics (Electronics) - Our Avionics group works to design, develop, test, analyze and integrate all the electronic hardware and software for our vehicles. This includes but is not limited to: flight software, flight computers, power conversion units, analog and digital circuit boards, FPGA’s, communication system units, guidance, navigation and control as well as enclosure and wire harness development. RF Test Engineer Responsibilities Responsible for development and execution of testing strategies for RF products spanning PCBA board testing, full functional testing of LNAs, transceivers, receivers, transmitters, radar, filters and antennas. Write Verification Test Plans, Test Procedures, and Test Reports against product requirements Expert with RF test equipment and measurement techniques to verify and validate product requirements. Work closely with Design Engineers, Manufacturing Engineers, and Production Test Labs to ensure a testable product is being developed and influence design to increase product reliability and test coverage. Make recommendations for design, process improvements, and data collection. Develop requirements for test racks/ATEs to be deployed to Production working with Hardware Engineers to build and develop custom test equipment for integration. Create automation software to interact with ATEs, Unit Under Test, instrumentation, and production systems to implement test plan in a fast moving production environment. Assist Design Engineers with setting specifications and test line limits using statistical analysis of data and measurement uncertainty analysis. Root-cause analysis of test failures and communicating recommended actions. Develop modular, reusable test architectures for manufacturing test and engineering design verification. Define and implement project plans, manage milestones and hold reviews to assure reliable test systems are delivered to production. Basic Qualifications: Bachelor’s Degree in Electrical Engineering or related technical degree required. Minimum 5 years experience with RF measurement techniques and technologies. Ability to write object-oriented software as part of a team Extensive understanding of RF instrumentation and measurements including Spectrum Analyzers, Signal Generators, VNAs, Power Meters, Noise Sources, Software Defined Radio, BER, EVM, Spectral Mask, ACPR, Noise Figure, IP3 and other non-linear distortions, and phase noise. Strong understanding of RF electrical components and architectures including mixers, filters, diplexers, directional couplers, power splitters, attenuators, oscillators, PLLs, RF switches, and μcircuits. Preferred skills: Masters Degree preferred. Certified LabVIEW Architect highly preferred. Experience with various modulation and coding schemes including BPSK, SOQPSK, GFSK, CDMA, SQPN. Familiarity with NASA's TDRSS SNUG guidelines is a plus. Understanding of metrology, sources of measurement error, and uncertainty analysis for RF measurements. Familiarity with SMT lines and RF device manufacturing. Experience with Python, LabVIEW FPGA, C++ and unit testing/continuous integration Familiarity with National Instruments and Keysight platforms including DAQmx, PXI, RIO, FlexRIO, SDR, USRP, PNA, PXA, and ESG. Understanding and experience in environmental testing such as vibration, shock, thermal, burn-in, and TVAC. Experience with production test solutions involving Mass Termination and scalable/modular hardware and software solutions for test. ITAR Requirements: To conform to U.S. Government space technology export regulations, applicant must be a U.S. citizen, lawful permanent resident of the U.S., protected individual as defined by 8 U.S.C. 1324b(a)(3), or eligible to obtain the required authorizations from the U.S. Department of State. Learn more about ITAR here.SpaceX is an Equal Opportunity Employer; employment with SpaceX is governed on the basis of merit, competence and qualifications and will not be influenced in any manner by race, color, religion, gender, national origin/ethnicity, veteran status, disability status, age, sexual orientation, gender identity, marital status, mental or physical disability or any other legally protected status.

-

Please contact Dave Bowers at David.Bowers@spacex.com for further inquiries. Engineer The Future SpaceX is a U.S.-based advanced technology company founded by residing CEO and CTO, Elon Musk. Founded in 2002, SpaceX builds rockets and spacecraft from the ground up, including cutting edge electronics, software, vehicle structures, and engine systems. The Falcon Launch Vehicle and Dragon Spacecraft programs are some of the most ambitious engineering systems in the world, designed to support our ultimate goals of aviation-like spaceflight capability and making humanity a multi-planet species. Our team is made up of more than 3,000 SpaceXers located across our Hawthorne, California headquarters; and other facilities in Florida, Texas, and Washington, DC. Advance the course of human history and pave the ways to Mars This is SpaceX. We are not like most companies. Our goal is to do what has never before been done--enabling mankind to live on other planets. We push the boundaries of what is currently possible, and understand it takes rare individuals to help us make this happen. We celebrate our successes, and each other. We seek future colleagues with a rare mix of drive, passion, scrappiness, intelligence, and curiosity to seek what’s beyond the stars. Playing a direct role in advancing the course of human history is no small endeavor. Join us, and find your place in the SpaceX legacy. The Department Avionics (Electronics) - Our Avionics group works to design, develop, test, analyze and integrate all the electronic hardware and software for our vehicles. This includes but is not limited to: flight software, flight computers, power conversion units, analog and digital circuit boards, FPGA’s, communication system units, guidance, navigation and control as well as enclosure and wire harness development. Sr. Avionics Test Engineer Responsibilities: Responsible for development and execution of testing strategies for avionics hardware spanning PCBA board testing, sensor/transducer verification, and full functional testing of an assembled unit. Design Verification Test Plans, Test Procedures, and Test Reports against product requirements to maximize Test Coverage. Expert with test equipment and measurement techniques to verify and validate product requirements. Understanding of electrical schematics and electronics manufacturing to analyze and improve test coverage. Work closely with Responsible Engineers, Manufacturing Engineers, and Production Test Labs to ensure a testable product is being developed and influence design to increase product reliability and test coverage. Make recommendations for design, process improvements, and data collection. Development of test racks/ATEs to be deployed to Production. Create automation software to interact with ATEs, Unit Under Test, instrumentation, and production systems to implement test plan in a fast moving production environment. Assist Design Engineers with Engineering Validation of designs, specification setting, and test line limits using statistical analysis of data and measurement uncertainty analysis. Root-cause analysis of test failures and communicating recommended actions. Develop modular, reusable test architectures for manufacturing test and engineering design verification. Define and implement project plans, manage milestones and hold reviews to assure reliable test systems are delivered to production. Evangelize and drive Design for Test (DFT) best practices and Design for Manufacturing (DFM) with Design Engineers and Manufacturing Engineers. Find systematic problems impacting First Pass Yield and drive solutions. Mentor engineers and propose solutions to Test Engineering as well as driving initiatives which require cross-group collaboration. Basic Qualifications: Bachelor’s Degree in Electrical Engineering or related technical degree required. Minimum 7 years of experience in Electronics Test Engineering. Proven tract record of holistic test solutions covering PCBA to assembly level. Show proficiency developing hardware and software test architectures and frameworks for increased efficiency and reliability. Experience in developing maintainable object-oriented software solutions. Comprehensive understanding of electrical engineering and electronics. Extensive understanding of instrumentation, interfaces and sensors including DMMs, DAQ, Power Supplies, Oscilloscopes, DIO, GPIB, USB, Serial-422, VISA, UDP, GigE, SPI, switch technologies and topologies, accelerometers, RTDs, thermocouples, and 4-20mA sensors. Familiarity with SMT lines and electronics manufacturing. Preferred skills: Masters Degree. Certified LabVIEW Architect highly preferred. Understanding of metrology, sources of measurement error, and uncertainty analysis. Experience with Python, LabVIEW FPGA, C++ and unit testing/continuous integration. Familiarity with National Instruments platforms including DAQmx, PXI, RIO, and TestStand. Understanding and experience in environmental testing such as vibration, shock, thermal, burn-in, and TVAC ITAR Requirements: To conform to U.S. Government space technology export regulations, applicant must be a U.S. citizen, lawful permanent resident of the U.S., protected individual as defined by 8 U.S.C. 1324b(a)(3), or eligible to obtain the required authorizations from the U.S. Department of State. Learn more about ITAR here. SpaceX is an Equal Opportunity Employer; employment with SpaceX is governed on the basis of merit, competence and qualifications and will not be influenced in any manner by race, color, religion, gender, national origin/ethnicity, veteran status, disability status, age, sexual orientation, gender identity, marital status, mental or physical disability or any other legally protected status. Applicants wishing to view a copy of SpaceX’s Affirmative Action Plan for veterans and individuals with disabilities, or applicants requiring reasonable accommodation to the application/interview process should notify the Human Resources Department at (310) 363-6000. Connect With Us Want to learn more about SpaceX career opportunities and culture? Be sure to connect with our recruiting team on social media: Twitter, Facebook, LinkedIn, Tumblr, and SpaceX Careers.

-

- labview

- certified labview architect

-

(and 3 more)

Tagged with:

-

Hi, I have a big project to manage which includes :-TestStand + LabVIEW-SQL Database for test inputs (UUT characteristics, sequences parameters,...) -HTML Reports -almost 10000 different part numbers (that's THE point) with common characteristics (almost 3000 families) + specific characteristics Everything has to be imaginated. The SQL inputs tables have to be created. The number of sequences to code has to be reduced to the minimum because, of course, it's impossible to code 8000 sequences differents files... The final solution must be as simple as possible. Possible ways of reflexion : -XML and Xpath for families and their children -Intermediate LabVIEW OOP layer for families and their children -Dynamically created sequences + variables (TS scripting)-Dynamically created sequences (concatenating a bunch of generic sequences to build a specific sequence) There is a lot of documentation about TestStand and SQL, but only for results (outputs), not really about inputs. Does anybody manage this kind of project ? In which way ? What would be your advices ? Thanks, Sébastien CLA

-

I was Googling around on the subject of graphical programming and open source and came across this. I have never seen it before. It looks pretty rough and new, but also very familiar. Seems to be Java-based. I have not yet downloaded it. Has anyone else seen this? Opinions please. http://www.zaluum.com/index.html

- 20 replies

-

Established start-up seeks experienced LabVIEW developer. Develop and maintain large technical engineering software applications in LabVIEW. Note there is no data acquisition/hardware development required. Location is western Sydney. Please PM me to apply. A. MAIN DUTIES 1. Design, develop, verify and document new software applications from concept to deployment. 2. Maintain and upgrade existing software applications. 3. Be involved in consulting and project work surrounding both areas of expertise of the business and applications which the software has been designed for and beyond. 4. Be involved in technical training seminars. 5. Develop and/or contribute to technical research publications. 6. Develop company standards documents; technical, non-technical, quality, procedures etc. with input from engineers and other parties as required. 7. Provide technical support and advice both internally and to customers and clients. 8. Develop technical procedures which assist with the company achieving and maintaining ISO 9001 quality accreditation. B. SELECTION CRITERIA • Honours degree in Electrical/Electronics Engineering or Computer Engineering. • Experience in developing medium to large LabVIEW software applications. • Knowledge and experience planning and developing software algorithms. • Experience with other programming languages. • Knowledge of electrical/electronics systems modelling concepts would be advantageous. • Knowledge of object-oriented principles and patterns would be advantageous. • Knowledge of cloud-based application deployment would be advantageous. • Knowledge and experience applying formal software lifecycle processes ensuring quality. • Experience writing technical documents. • Proficiency in using Microsoft Office products. C. DESIRABLE ATTRIBUTES • Excellent team working ability. • Conceptual and analytical problem solving ability. • Detail oriented with a high-level of organization. • Excellent written and verbal communication skills. • Driven and motivated with a passion for learning. • Resourceful, investigative and innovative.

-

Hi, guys, From the attached image, you can see a stellar form image in black, and some annotation in x, y, d, w , r . x and y are just that we use in cartesian coordinate system; and d is the maximum dimension of the image, which is the span of the particle projected onto a line determined by a least-squares fit of the x and y positions of all occultations; w is the span of the particle projected onto the line perpendicular to that used for d; and r is the correlation coefficient from the least-squares fit. The data of the image is structured in an array with 0 and 1, which is very easy for me to get the dimension in x and y direction. But i really don't know how to get the dimension d, w and r in least-squares fit methods. If i want to realize it in labVIEW G language, can you give me some tips or codes in LabVIEW. Thanks!

- 2 replies

-

- least-squares fit

- labview

-

(and 1 more)

Tagged with:

-

Hi everyone, so we have a device for measurement & signal generation and want to make it accessible through VISA say by Ethernet / USB / Serial. Other than the VISA driver template and the SCPI parser that must be implemented on the device, does anyone offer a good starting point on how to make a device talk VISA and maybe even get it certified by NI? Thanks in advance

-

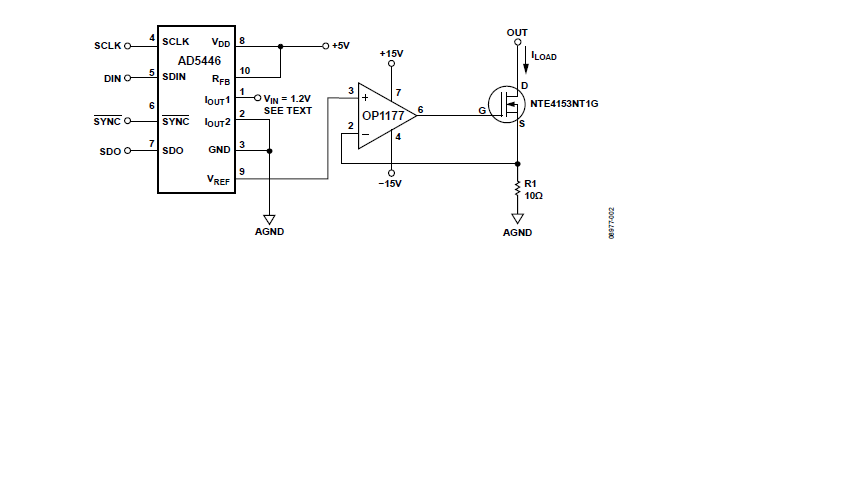

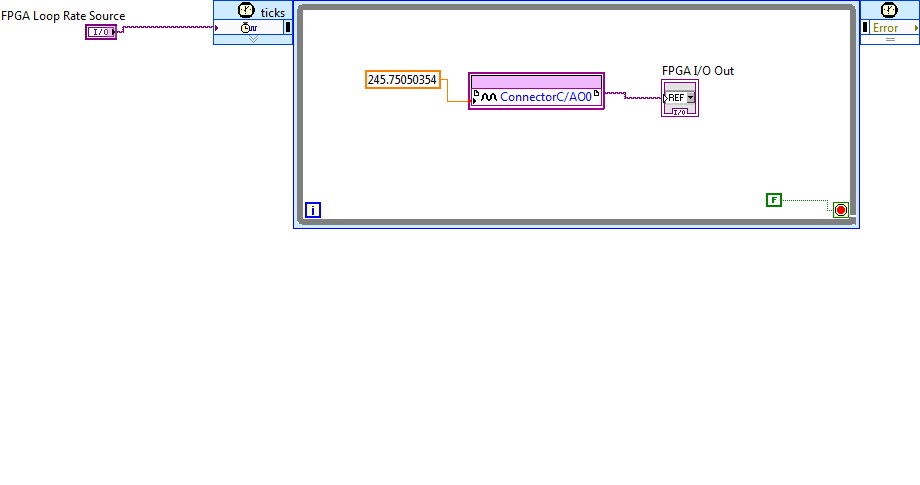

I am trying to drive a proportional solenoid valve: PVQ-33-5G-23-01N ( which responds to currents between 100mAand 165mA. I am using a circuit similar to the one in the attachment below except that I am using the myRIO's DAC in place of the AD5446, the LM324(http://www.ti.com/lit/ds/symlink/lm124-n.pdf) in place of the OP1177 and the MOSFET(http://www.mouser.com/Search/ProductDetail.aspx?R=VN3205N3-Gvirtualkey68900000virtualkey689-VN3205N3-G)[/url] So the challenge I am having is how to configure the circuit in labview. I am trying to use the default FPGA person ality of myRIO. I am supposed to generate a 1.2V Vref signal into the pin 3 of the LM324. By varying the word that is sent to the LM324, I am supposed to effectively vary the current on the Drain terminal of the mosfet. I have wired the Vref terminal to Connector C/AO0 on the myRIO and I have the VI below but I have no experience sending bits and bytes. I would love to drive the solenoid with about 10 -15 steps of current. Any help would be appreciated.

-

I have a C# code which I have compiled as a DLL class. It basically employs a Kinect camera to track an object and then spills distance of the camera from the object to a console window. How do I retrieve the distance (given in the console window when I run the C# executable file) by calling the .NET assembly in labview. Thank you!

-

Dear all, I have not been posting here for a while (Yes, I was an active member here). I hope all of you doing well. I am setting up a forum which it would be good if you are willing to make a few posts. It is not directly related to LabVIEW, but it could be a platform to run Labview in the future. I am talking about Project Ara. Please also feel free to put a couple post in Ara PUB. I copy the idea of Lava Lounge. Once more thing, the forum has money prizes and lucky draw. I hope that you will enjoy it. http://www.projectaratalk.com Superhero

-

Hi Lava, I'm having an issue with a teststand deployment (Teststand 2013, LabVIEW 2013) I have a deployment which deploys my LabVIEW project containing all drivers (classes and lvlibs) for use in my sequences. In the deployment (LabVIEW options), I uncheck "exclude vi.lib", "exclude user.lib" and "exclude instr.lib" because the deployment should also work on an PC that only has runtimes and an operator interface. The build finishes without errors but I cannot open the deployed project... --> not on a development PC because it finds conflicts (XNodeSupport and some vi's in vi.lib picture.llb) --> not on a runtime PC (file not found) Did anyone else notice the same behaviour ? Thanks in advance for your help, tips and tricks :-) At first, i thought i had something to do with LabVIEW search paths (because I include vi.lib, it should not search for the vi's in the real vi.lib) but that didn't help... http://lavag.org/topic/18620-labview-search-paths/#entry111920

-

I want to load hex file into avr microcontroller using labview...How it is possible?? Details-----atmega64 controller based avr kit ..and it has USB interface for programming ....I load program using winAVR but now i want to load hex file using labview ..

-

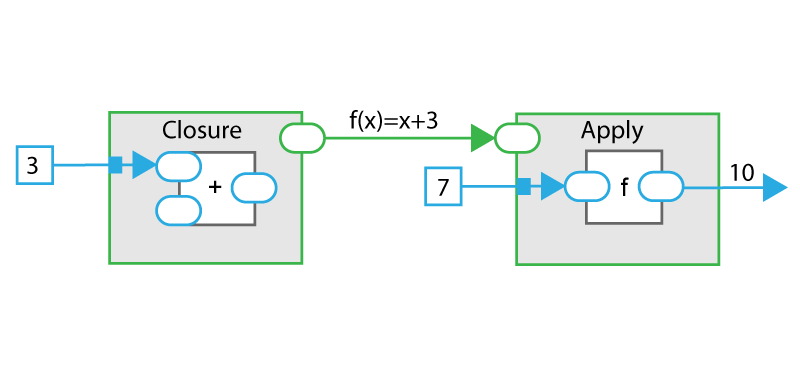

When I originally selected the name for my blog ExpressionFlow back many years ago, what I had in mind was functional dataflow programming and the ability to pass any subdiagrams (expressions) around as first class citizens of the language. Functional programming languages (haskell, clojure, lisp) have a lot in common with dataflow world. In principle, calling a function in a functional language is identical to calling a node in a visual language. Passing data between functions happens in an immutable way in functional languages, similar to the concept of data flowing between nodes in a flow-based programming languages. Monads determine execution order of functions with side effects, the same way as flow diagrams determine the execution order of nodes in LabVIEW. Functional programming is often seen as an alternative to object oriented programming. One can solve similar problems of dynamic dispatching either by passing functions around or passing objects with methods around. There are of course multi-paradigm languages supporting both objects and functions like Clojure and Scala. So what would LabVIEW look like if it supported concepts of functional programming paradigm? I posted an article on this on ExpressionFlow and I am intending to study the concept on ExpressionFlow in my future posts. Would you use functional LabVIEW if such a language existed? My post on how a functional programming could appear in a visual dataflow language: Synchronous Functional Dataflow Programming & Closures of Named Functions p.s. See Joel's quick intro to functional programming if you are unfamiliar with the concept of functional programming.

- 7 replies

-

- functional programming

- dataflow

-

(and 1 more)

Tagged with:

-

Hi, I want to adjust the search paths in LabVIEW and i was wondering if I can add an entry to search the 'current project path' including subdirs. (a bit like teststand, current sequence path and subdirs) Reason: I have a few testsystems which run a teststand operator interface and a source distribution of my drivers (vi.lib, instr.lib and user.lib included) However... we have one system with teststand and labview development, for debug and test. If I build a project (teststand deployment) of my drivers, I get them in 1 folder structure. A projectfile with ALL subvi's needed vi.lib, instr.lib and user.lib included.... works on the testsytems BUT when I open this project in the dev env... the project has conflicts on Xnode support, picture to pixmap, Imagedata.ctl, .... I think that adding a search path in LabVIEW to search 'Current ProjectDir' including subdirs will solve my problem but I don't know the syntax for 'current project dir' don't even know if this is possible. Thanks for your reply. Wim

-

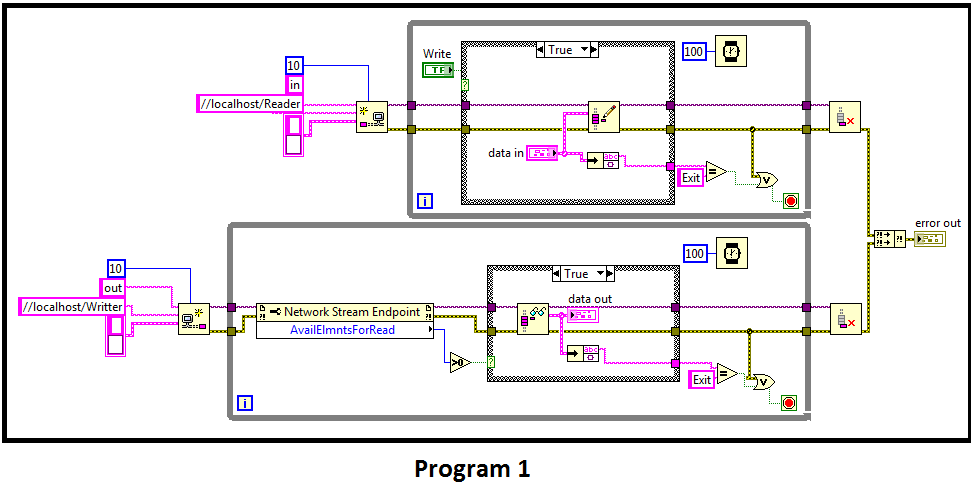

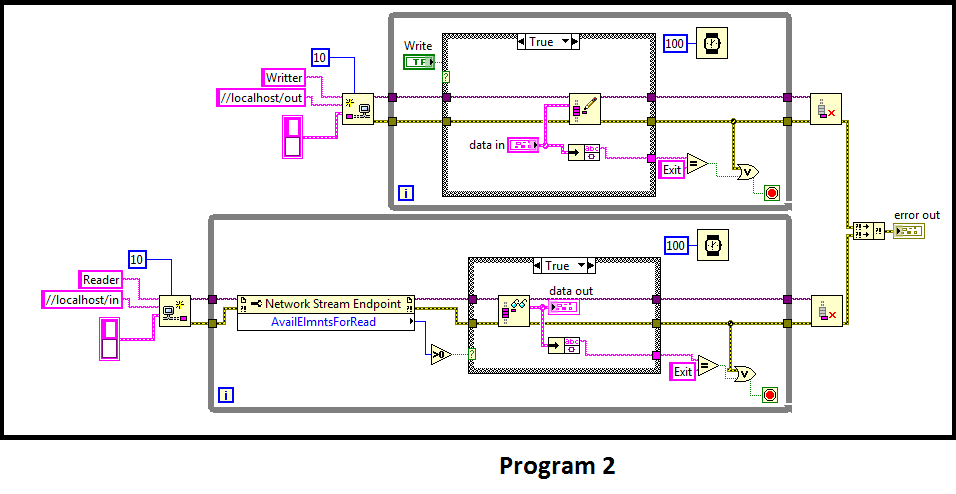

I'm trying to find a way to communicate between two executable LabView app, because of several reasons I chose (associated with my application) Network Streams. Everything works fine so long as they are the VIs. When I build exe files there is no communication between apps. The apps waits forever for connection (because there is no timeout). Did anybody meet the same problem? I will be very grateful for any advices and comments. TestStream.vi TestStream2.vi

- 3 replies

-

- network stream

- labview

-

(and 2 more)

Tagged with:

-

I need to protect an excel worksheet, and I use "USERINTERFACEONLY" As i also require some formatting such as merge cells and other option I use "ALLOWFORMATTINGCELLS" But I'm not able to run it... it say unlock and than run.... I do not want to unlock do modification and than lock method... Is there an alternative??? p.s. It works with kingsoft not with excel 2010...what?

-

I am currently working on a NI 9626 sbRIO with other external hardware using LV 2013. My issue is that my webservices will not load when I deploy the project as a startup application. I am able to manually click and publish the webservices, as well as manually right click and deploy the build. The webservices then run fine, and are publishing data from the application that is running. But for some reason, the board cannot seem to do both at the same time and on deployment as a startup. There are no errors, it acts like it deploys fine but then webservices never load and neither does the startup vi. Is there something I am missing that’s required in the build process to make webservices publish correctly on deployment as a startup? Thanks Edit: I have also posted this here http://forums.ni.com/t5/LabVIEW/Webservice-publishing-with-a-RT-startup-application/m-p/3019461/highlight/false#M862896 One thing I do notice however when I do try to run as startup is that when I try to login to the NI webservices config page I get this error:

-

- labview

- webservice

-

(and 1 more)

Tagged with:

-

I need to build a system where I have to control 4 or 5 small solenoid valves independent of each other using LabVIEW. I have two options: 12 V DC, 2W or 12/24 V DC, 6W. I am really new to LabView and interfacing. So this may sound dumb: 1.Do I need Arduino or some other kind of embedded system for controlling the valves? Or labview has some kind of module for that? 2.Will each of the valves need separate power source? Any suggestions are welcome. Thanks

- 4 replies

-

- solenoid valve

- instrument control

-

(and 1 more)

Tagged with:

-

Hi Everyone, Erdos Miller is looking to expand our consulting and integration business based around NI products. We are a team of ~35 engineers headquarted in Houston with a few remote workers around the world. We provide contract engineering services, consulting, training, and we also develop our own products for the Oil and Gas industry. To expand our consulting and integration business we're looking for two types of people: 1) Technical People with an Entreprenurial Mindset - We're looking for someone technical, ideally with LabVIEW experience, who's looking to take on something new. Ideally you will go out into the world to find excellent projects to work on and clients to work with. We would see this position as a mixed technical and sales and marketing position. You would handle customer relations, conceptual designs, proposal and contract development and oversee, even sometimes aid the team in the development of projects. This position would be the perfect mix of systems engineer and sales, a sort of intraprenuership if you will. 2) LabVIEW Gurus - CLD/CLA Level - You're passionate about LabVIEW, have at-least 3-5 years of experience, and have some really cool automation experience you can show off. You'll join our team of LabVIEW developers headquarted in Houston and complete challenging, exciting consulting projects. Ideally you have a degree in some sort of engineering and have some technical proficiency outside of LabVIEW. Ideally you live in Houston, Austin, or Dallas and can work in the United States. We have excellent benefits, a start-up feel, a passionate team and a flexible work life. We're at NI week this week so if you can grab us while we're here, that would be great! If not here's how you can contact us: - A private message on this forum. - On Twitter: #erdosmiller - By phone: 713-562-4315 - By email: ken AT erdosmiller DOT com You can find us on the web at www.erdosmiller.com. Ken Miller Cofounder, CLD Erdos Miller

-

- entrepreneurship

- labview

-

(and 3 more)

Tagged with:

-

Hi, I am new to this group, so if the post is not in some proper format, I apologize. I am trying to communicate Agilent 8563EC series Signal Measurement equipment. Using the example vi of controlling that instrument, I am trying to modify it to grab the center frequency from the instrument instead of popping the value from labview it self, i.e. I am trying to convert the center frequency from a control to a indicator. But, when I am trying to set the center frequency from the instrument, it is not showing up in labview programmed interface, instead it is changing the value in the instrument itself to 13 GHz, though I am giving it 55 MHz from the instrument. The value is showing properly when I am running the subvi of center frequency alone, but when I am trying to run the complete VI, it is inserting a garbage value in labview as well as changing my instrument parameter of center frequency. Please Help! Thanks.

- 1 reply

-

- labview

- instrument

-

(and 1 more)

Tagged with:

-

Hello, In matlab the plot data can be save as a *.png,*.jpeg, and so on and even a pretty good option *.fig. Later when the *.fig is opened you have the real plot as before and this can be edited like changing the legeng , x and y labels, color of the plot etc,. Is there any option like this in labVIEW. I have seen options like saving the data into excel and to different image formats. Is there any special tool kit or add in functions??

-

Hello All, My current company is in the process of expanding, and we are seeking experienced LabVIEW developers for our Boston office location. Please see below for position details: Automation Engineer – LabVIEW Control Systems DMC has openings in several automation engineering positions, based on experience level. Location Boston, MA Job Summary With a broad understanding of engineering fundamentals, DMC Automation Engineers provide programming, troubleshooting, testing & measurement, and technical support & solutions to a wide range of clients. Automation Engineers quickly learn new technologies and absorb specific industry knowledge to provide custom software engineering, problem solving, and helpful assistance during each phase of a project. Working both independently and within teams, Automation Engineers assist with project management, meeting deadlines and keeping excellent communications and feedback channels with team members and clients. Minimum Qualifications Engineer Level I (1-3 years relevant experience):Bachelor of Science in Mechanical, Electrical, or Computer Engineering, Computer Science or related field Background in LabVIEW Programming Engineer Level II (2-5+ years relevant experience): In addition to the above requirements, several years of experience with design and implementation of LabVIEW projects Certified LabVIEW Developer or Certified LabVIEW Architect Project-based development experience Desired ExperienceReal-Time FPGA cRIO PXI RF Vision CAN Modbus Required Skills Engineer Level I Programming Quickly Learn New Technologies Complete grasp of scientific method of problem solving Ability to follow patterns & build upon established models Understanding complex system designs Estimation of time to complete familiar tasks. Identify & communicate through proper channels new opportunities for DMC Engineer Level II (In addition to above skills)Experience with current test and measurement as well as data acquisition hardware and devices. Ability to specify correct hardware based on system requirement. Project Planning/System Architecture Design Program Implementation Debug System Testing Communication with team members and clients Documentation Ability to create methodology to solve novel problems Ability to design systems based upon previously used system Convey knowledge in presentations, SOPs, Knowledgebase articles, client case studies, and white papers Estimation of own and others' time for completion of familiar tasks Project proposal writing Other Skills/Abilities Customer Service Communications Technical Writing General Admin Responsibilities Engineer Level IProgram applications to meet & exceed customer requirements Develop robust applications in accordance with DMC programming standards & best practices Project Planning/System Architecture Design Assistance Program Implementation Debug System Testing Communication with team members and clients Documentation Respond to customer needs Engineer Level II (In addition to above responsibilities) Perform programming and engineering tasks in supportive and leading roles at all stages of projects. System design and design assistance. Help Train/Orient/Bring Up to Speed new employees. Convey knowledge in presentations, SOPs, Knowledgebase articles, client case studies, and white papers. Develop & maintain relationships with key contacts with vendors. Develop & maintain relationships with clients, keeping feedback channels open and healthy. Assist in writing project proposals. Seek, identify, and discuss new opportunities with new & existing clients, through proper DMC channels. Interested? Email your resume and cover letter to: jobs@dmcinfo.com Full Listing: http://www.dmcinfo.c...control-systems General Information: http://www.dmcinfo.com